Petroleum naphtha (Environmental & Earth Science)

Contents

Petroleum naphtha

Petroleum naphtha is an intermediate hydrocarbon liquid stream derived from the refining (Petroleum refining processes) of petroleum crude oil.[1][2][3] It is most usually desulfurized and then catalytically reformed, which re-arranges or re-structures the hydrocarbon molecules in the naphtha (as well as breaking some of the molecules into smaller molecules) to produce a high-octane component of gasoline (petrol).

There are quite literally hundreds of different petroleum crude oil sources worldwide and each crude oil has its own unique composition or assay. There are also hundreds of petroleum refineries worldwide and each of them is designed to process either a specific crude oil or specific types of crude oils. That means that it is virtually impossible to provide a definitive, single definition of the word naphtha since each refinery produces its own naphthas with their own unique initial and final boiling points and other physical and compositional characteristics. In other words, naphtha is a generic term rather than a specific term.

In addition, naphthas may also be produced from coal tar, oil shale deposits, tar sands such as in Canada, the destructive distillation of wood, and coal gasification or biomass gasification to produce a synthetic gas (syngas)[4][5] followed by the Fischer-Tropsch process to convert the syngas into liquid hydrocarbon products. For that reason, this article is entitled "Petroleum naphtha" and deals only with naphthas produced by the processing of crude oil in petroleum refineries.

The major source of petroleum naphtha in a petroleum refinery

The first unit process in a petroleum refinery is the crude oil distillation unit. The overhead liquid distillate from that unit is called virgin or straight-run naphtha and that distillate is the largest source of naphtha in most petroleum refineries. The naphtha is a mixture of very many different hydrocarbon compounds. It has an initial boiling point (IBP) of about 35 °C and a final boiling point (FBP) of about 200 °C, and it contains paraffin, naphthene (cyclic paraffin) and aromatic hydrocarbons ranging from those containing four carbon atoms to those containing about 10 or 11 carbon atoms.

The virgin naphtha is often further distilled into two streams:[6]

- a virgin light naphtha with an IBP of about 30 °C and a FBP of about 145 °C containing most (but not all) of the hydrocarbons with 6 or less carbon atoms.

- a virgin heavy naphtha containing most (but not all) of the hydrocarbons with more than six carbon atoms. The heavy naphtha has an IBP of about 140 °C and a FBP of about 205 °C.

It is the virgin heavy naphtha that is usually processed in a catalytic reformer because the light naphtha has molecules with 6 or less carbon atoms which, when reformed, tend to crack into butane and lower molecular weight hydrocarbons which are not useful as high-octane gasoline blending components. Also, the virgin light naphtha molecules with six carbon atoms tend to form aromatics which are high-octane components but which are undesirable because they are carcinogens (most particularly benzene) and governmental environmental regulations in a many countries limit the amount of aromatics that gasoline may contain.[7][8][9]

Types of virgin naphthas

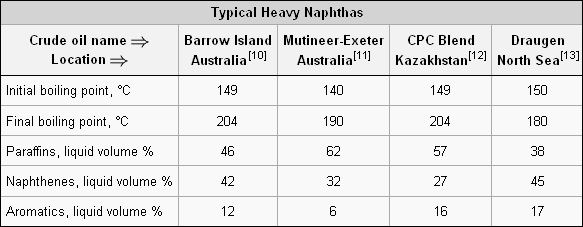

The table just below lists some fairly typical virgin heavy naphthas, available for catalytic reforming, derived from various crude oils. It can be seen that they differ significantly in their content of paraffins, naphthenes and aromatics:Cracked naphthas

Olefinic hydrocarbons do not occur in petroleum crude oil and hence the virgin naphthas produced in petroleum refineries do not contain olefins. However, certain refinery naphthas do contain some olefinic hydrocarbons which are produced by some of the processing units within a refinery. For example, naphthas derived from the thermal cracking that occurs in fluid catalytic crackers, visbreakers and coking processes contain olefins and are commonly referred to as cracked naphthas.

In some (but not all) petroleum refineries, the cracked naphthas are desulfurized and catalytically reformed (as are the virgin naphthas) to produce additional high-octane gasoline components.

Removal of sulfur compounds from naphthas

Most uses of petroleum refinery naphtha require the removal of sulfur compounds down to very low levels (a few parts per million or less). That is usually accomplished in a catalytic chemical process called hydrodesulfurization which converts the sulfur compounds into gaseous hydrogen sulfide that is then removed from the naphtha by distillation.

The hydrogen sulfide gas is subsequently captured in amine gas treating units and converted into byproduct elemental sulfur. In fact, the vast majority of the 68,000,000 metric tons of sulfur produced worldwide in 2010 was byproduct sulfur from petroleum refining and natural gas processing plants (which also use amine gas treating units to remove hydrogen sulfide from the raw natural gas).[14][15]

In lieu of hydrodesulfurization, light naphthas may be treated in a Merox unit to remove any hydrogen sulfide and, more particularly, to remove sulfur compounds called "mercaptans".

Uses other than processing to produce high-octane gasoline components

Some petroleum refineries also produce small amounts of specialty naphthas for use as solvents, cleaning fluids, paint and varnish diluents, asphalt diluents, rubber industry solvents, in dry-cleaning, in cigarette lighters, and in portable camping stove and lantern fuels. Those specialty naphthas are subjected to various purification processes.

Sometimes the specialty naphthas are called petroleum ether, petroleum spirits, mineral spirits, paraffin, benzine, hexanes, ligroin, white oil or white gas, painters naphtha, refined solvent naphtha and Varnish makers' & painters' naphtha (VM&P) . The best way to determine the boiling range and other compositional characteristics of any of the specialty naphthas is to read the manufacturer's Material Safety Data Sheet (MSDS) for the specific naphtha of interest.

On a much larger scale, petroleum naphtha is also used in the petrochemicals industry as feedstock to chemical processes (referred to as steam reforming and steam cracking) for the production of ethylene and other olefins as well as for the production of hydrogen for use in the manufacture of ammonia for fertilizers. Natural gas is also used as feedstock to steam reformers and steam crackers.

References

- J.H. Gary and G.E. Handwerk (1984). Petroleum Refining Technology and Economics, 2nd Edition, Marcel Dekker, Inc., ISBN 0-8247-7150-8.

- W.L. Leffler (1985). Petroleum refining for the nontechnical person, 2nd Edition, PennWell Books, ISBN 0-87814-280-0.

- James G. Speight (2006). The Chemistry and Technology of Petroleum, Fourth Edition, CRC Press, ISBN 0-8493-9067-2.

- SASOL's Coal-to-Liquids technology. From the SASOL website.

- M.R. Beychok, Process and environmental technology for producing SNG and liquid fuels, U.S. EPA report EPA-660/2-75-011, May 1975

- Fuel Chemistry. Scroll down to the "What is Naphtha?" section.

- Benzene in Canadian Gasoline. Scroll to Table 2.1 on pdf page 11 of 65 pdf pages.

- Benzene From Traffic. From the website of the National Environmental Institute (NERI) of Denmark. Scroll down to the "Summary" on pdf page 8 of 46 pdf pages for the European Union's limit for benzene in petrol (gasoline).

- Control of Hazardous Air Pollutants From Mobile Sources. 40 CFR (the U.S. Code of Federal Regulations) Part 8O, published in the Federal Register, Volume 73, Number 201, Oct.16, 2008. Scroll to the "Background" section on page 61359.

- Barrow Island crude oil assay.

- Mutineer-Exeter crude oil assay.

- CPC Blend crude oil assay.

- Draugen crude oil assay.

- Sulfur Report, U.S. Geological Survey, Jan. 2011

- Discussion of recovered byproduct sulfur.