Life cycle assessment of farming systems

Contents

Life cycle thinking

In order to survive and lead fulfilling lives all humans must satisfy certain needs. One of the strategies that people adopt to satisfy their needs is the consumption of a wide spectrum of goods and services which are traded on global and local markets. These different products or services generally have a long story occurring over time and space. It starts with the extraction of raw materials, the production and transportation of the components of the product, followed by the production of the product itself up to its consumption and final disposal or recycling. This story is called the “cradle-to-grave” life cycle. The Integrated-Product Policy of the European Union states: “All products cause environmental degradation in some way, whether from their manufacturing, use or disposal.”

Environmental efficiency

The traditional way to address environmental problems was to focus on a plant or a site of production and most often on one particular pollutant. However, this approach often leads to problem shifting, either from one stage of the life cycle to another or from one environmental problem to another, simply by converting the pollution into another form. In order to minimize the environmental impacts of a product or a service, one needs to compare the overall (“cradle-to-grave”) environmental efficiency (impact per kilogram [kg] of product or per unit of service) of different ways of producing it and for a comprehensive range of environmental problems. Covering the whole life cycle of a product also allows identifying the hot spots where most gains can be achieved with least effort and costs.

The methodology

A normalized methodology

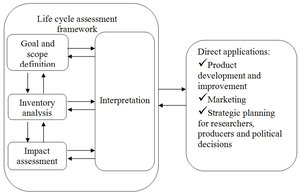

Life Cycle Assessment (LCA) is a normalized methodology which formally describes the four steps to follow to achieve the environmental assessment of a product or service over its life cycle (Fig. 1). It is based on an inventory of the resources consumed (e.g. energy, ore) and the emissions to the environment at each stage of the life cycle of this product. The different inventory data (resources and emissions) are first quantified, then aggregated over the whole life cycle and classified into specific environmental impact categories (e.g. climate change, eutrophication, toxicity). The conversion of the inventory data into an indicator value for each impact category allows delivering a synthetic and quite exhaustive picture of the environmental efficiency of the studied product. The results are expressed per unit of the studied product or function, called functional unit and which will often be a unit of mass of the product of a certain quality, e.g. one kg of energy-corrected milk, which takes account of the fat and protein content of the milk.

History

The history of LCA goes back almost 40 years and started with energy and material budgets to which complementary pollution aspects were progressively added. With the two oil crises in the 1970s, interest in LCA was boosted, but mostly for the energy efficiency part. With the growing solid-waste issues at the end of the 1980s, the development of the methodology accelerated and in 1992 the first formal framework for the impact assessment phase was proposed. The purpose of this phase, based on scientific knowledge and models, is to convert inventory data into potential impacts on ecosystems and human health. The refining of this phase remains one of the key scientific challenges of the methodology for many research teams around the world. A first international norm was set up in 1997 describing the principles and the general framework of LCA (Fig. 1).

Illustration for a food product

LCA of food products

For more than ten years, LCA has been applied to a whole range of agriculture products: milk, pork, beef, chicken, salmon, trout, wheat, apple, wine, kiwifruit and biofuel. Most studies on food products generally concentrate on the “cradle-to-farm-gate” part of the life cycle because it has been identified as the main contributor to all impacts and in most situations, the next stages (transformation, distribution, consumption, final disposal) would be assumed to be similar for all studied scenarios. Moreover, the farm stage is also the most difficult to assess because of the interaction between farming systems and their environment. In the following we present a typical example of a cradle-to-farm-gate study.

Comparative LCA of three scenarios of pig production in France

Question: Is it better to produce pig respecting conventional good agricultural practices, organic rules of production or a French quality label (“Red label”)?

“Cradle-to-farm-gate” life cycle of pig production: This study compared three scenarios for pig production in France and dealt only with the processes up to and including the production on the farm. The most recent data available were used, mainly from the period 1996-2001. The Good Agricultural Practice (GAP) scenario corresponds to current intensive production (or “conventional” production), optimized in particular with respect to fertilization (Fertilizer) practices. In the GAP scenario pigs are raised at high density in a slatted-floor confinement building. The Organic (OA) scenario corresponds to organic agriculture according to the French version of the European rules for organic animal production. The Red Label (RL) scenario corresponds to the “Porc Fermier Label Rouge” quality label. In the OA and RL scenarios pigs are born and raised outdoors until weaning and in an open-front straw-litter building at low-animal density after weaning.

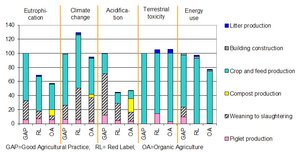

Results: Impacts were expressed by two functional units corresponding to the two main functions of an agricultural production system. Kg of pig produced (live weight at slaughter) reflects its function as a producer of market goods, whereas hectare (ha) of land used reflects its function as a producer of non-market goods (e.g. environmental service). Results per ha of land used are presented in Fig. 2.

Interpretation: When examined with particular emphasis on the most critical impacts of farming systems (compared to other activities): eutrophication, acidification and land use, the Red label scenario appeared as an interesting alternative to the GAP scenario on the condition that its emission of greenhouse gas can be reduced. The results were very dependent on the functional unit. Per kg of pig, eutrophication and acidification were similar for the Organic scenario and the GAP scenario (not shown), while the Organic scenario had less eutrophication and acidification than the GAP scenario when expressed per ha (Fig. 2). For the three scenarios, environmental hot spots and important margins for improvement were identified. For GAP, eutrophication and acidification linked with the housing of pigs, management of manure and the production of feed were the key hot-spots. For Red label, the straw bedding system was responsible for higher greenhouse gas emissions, while for Organic, the composting of manure in addition to the straw bedding system for pigs were hot spots.

As shown in this example, the LCA methodology has proved a valuable tool to assess the environmental impacts of farming systems and products. Providing a global picture of a problem, it allows making more relevant decisions for all types of stakeholders.

Other applications

The LCA methodology has been used to address a whole range of questions at different scales. Here are some examples of questions that LCA can help answer:

- Comparison of the environmental performance of different products to deliver the same function: E.g. what is the most eco-efficient way to produce 1 kg of protein? Is it as fish, beef, chicken or Soya bean?

- In a global economy, comparison of the environmental performance of the same products between countries with specific natural constraints and resources. E.g. where is it best to produce milk for the European market? Is it in New Zealand where pastures can reach a very high yield but markets are very distant, or locally in Europe?

- Comparison of agricultural practices, mitigation options? E.g. what is the best technology to apply liquid manure to a field?

- Give information to consumers to help them “green” their consumption.E.g. Food products that have been air-freighted have a high energy consumption and impact on climate change

- Eco-labeling

Further Reading

- Basset-Mens, C., van der Werf, H.M.G., 2005. Scenario-based environmental assessment of farming systems: the case of pig production in France. Agriculture, Ecosystems and Environment,105:127-144.

- Basset-Mens, C., 2005. Propositions for an adaptation of Life Cycle Analysis to agricultural production systems. Application for the environmental evaluation of pig production. PhD Thesis, in French (introduction and general discussion) and English (other chapters). Géosciences Rennes (Ed.), No 11, 242p, Rennes, France.

- Carlsson-Kanyama A., 1999. Consumption Patterns and Climate Change: Consequences of eating and travelling in Sweden. PhD thesis, Department of Systems Ecology, Stockholm University, Stockholm, Norway.

- Guinée, J.B., Gorrée, M., Heijungs, R., Huppes, G., Kleijn, R., de Koning, A., van Oers, L., Wegener Sleeswijk, A., Suh, S., Udo de Haes, H.A., de Bruijn, H., van Duin, R., Huijbregts, M.A.J., 2002. Life cycle assessment. An operational guide to the ISO standards. Centre of Environmental Science, Leiden University, Leiden, The Netherlands.

- Hayashi, K., Gaillard, G., Nemecek, T., 2005. Life cycle assessment of agricultural production systems: current issues and future perspectives. International Seminar on Technology Development for Good Agriculture Practice in Asia and Oceania, Epochal Tsukuba, 25-26 October 2005.

- Swedish Institute for Food and Biotechnology. Publications on LCA.

- The Life cycle initiative by UNEP and SETAC – International partnership for a sustainable world.