Growing Plants for Biofuel

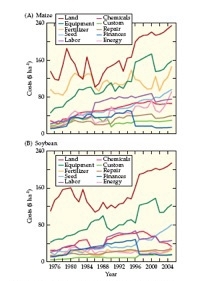

Estimates of greenhouse gas emissions during the production of biomass for biofuels often differ. [1] The greatest expense in growing plants for human use is the purchase of arable land; therefore, the profitability of biomass production depends on high yields, the economic productivity per unit of land area. This promotes the use of high-input agriculture that is likely to employ sophisticated farm machinery; adequate amounts of fertilizers, pesticides, and water; and new cultivars bred for high yields under these amounts of fertilizer, pesticides, and water. Grain yields in the United States have improved more than 50% during the past 30 years, an increase attributable in equal measure to altered agricultural practices and new genotypes. [2]

Application of nitrogen fertilizer dramatically enhances crop yields, but manufacture, distribution, and application of nitrogen fertilizer contributes the majority of greenhouse gases emitted during biomass production. A large portion of these greenhouse gases derive from the power demands of industrial nitrogen fixation, the extremely energy-intensive process that makes ammoniacal nitrogen (NH3) out of thin air. Moreover, nitrogen fertilization stimulates soil microorganisms that transform soil nitrogen into nitrous oxide (N2O), a greenhouse gas.

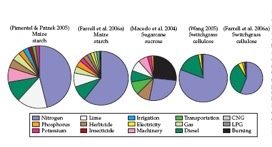

Estimates of greenhouse gas emissions during cultivation of crops for bioethanol. Pie sizes represent total emissions: From left to right are 0.31, 0.21, 0.10, 0.11, and 0.05 gram carbon equivalents per liter of ethanol. (After Land and Plant Nutrition Management Service 2004; Macedo et al. 2004; Pimentel and Patzek 2005; Wang 2005; Farrell et al. 2006a.)

Crop nitrogen use efficiency has almost doubled over the past 50 years. This improvement stems from both higher crop yields per amount of nitrogen absorbed from the soil and greater crop nitrogen absorption per amount of fertilizer applied. As a result, yield gains in the United States over the past 30 years have required little additional nitrogen fertilization and have generated few additional greenhouse gases. Here lies the promise of biofuels: the expanded cultivation of crops that require lower inputs of nitrogen, other chemicals, and water and less use of mechanical equipment to produce high, sustainable yields of biomass rich in organic carbon compounds that can be readily converted into fuels.

One promising source of biofuel is sugarcane (Saccharum officinarum). Brazil devotes about 10% of its farmland to sugarcane, and ethanol from sugarcane supplies about 14% of its fuel needs for vehicles. In prime growing regions of the tropics, fields of mature plants accumulate up to 20 kg of sucrose (table sugar) per square meter. Sugarcane in Brazil grows throughout the year and produces about 130 GJ (109 joules) of ethanol per hectare over 12 months, as compared to maize (corn) in the United States, which produces about 87 GJ of ethanol per hectare over 6 months. [3] Sugarcane serves as a host for nitrogen-fixing bacteria within its tissues and therefore maintains high productivity under relatively low nitrogen fertilization.

Farm management of sugarcane, like that of other biomass crops, must balance the practice of leaving stubble in the field to return vital nutrients and organic carbon to the soil against the practice of removing this material to serve as an energy source during processing. In Brazil, a large portion of the aboveground biomass is removed from the field and burned at the processing plants to provide both heat for distilling the alcohol and electricity to run the machinery. Still unknown is the long-term sustainability of such a practice. [3]

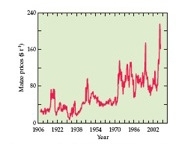

A major controversy concerning cultivation of maize and sugarcane for ethanol (or soybeans for biodiesel) is the diversion of food to fuels. In the past 2 years, the boom in maize-derived ethanol in the United States has contributed to a 50% increase in maize prices. These price increases resonate throughout the food chain, causing higher prices at the market because maize is a major feedstuff for meat and dairy cattle, and corn syrup is a major ingredient in many foods and beverages for humans.

Average farm price ($USD per metric ton) received for maize (corn) in the United States during the past century. (After Economic Research Service 2009.)

Another potential biomass crop, one which grows on lands unsuitable for cultivation of human food crops, is switchgrass (Panicum virgatum). Switchgrass produces prodigious quantities of biomass that is 33% cellulose, 26% hemicellulose, and 18% lignin. One can convert these constituents into ethanol with varying degrees of difficulty. Some scientists reckon that nitrogen, other chemicals, and water requirements for sustainable production of switchgrass are less than one-third those of maize. On this supposition—and a few others—hinges the future of the biofuels industry. Other scientists reckon that the input requirements for both crops are somewhat similar.

[1] Farrell, A. E., R. J. Plevin, B. T. Turner, A. D. Jones, M. O'Hare, and D. M. Kammen (2006b) Ethanol can contribute to energy and environmental goals. Science 311:506-508.

[2] Duvick, D. N. (2005) The contribution of breeding to yield advances in maize (Zea mays L.). Advances in Agronomy 86:83-145.

[3] Patzek, T. W. and D. Pimentel (2005) Thermodynamics of energy production from biomass. Critical Reviews in Plant Sciences 24:327–364.

This is an excerpt from the book Global Climate Change: Convergence of Disciplines by Dr. Arnold J. Bloom and taken from UCVerse of the University of California.

©2010 Sinauer Associates and UC Regents

2 Comments

Erich Knight wrote: 02-18-2011 13:35:28

Farm Fossil Fuel Solution Here is encouraging news from Biofuels Digest on the farmer's potential to eat his own fuels. Now combine that with char systems for reduction of the 17% fossil fuel fertilizer cost of crop production, or eliminate fossil carbon all together with the SynGest pathway, http://www.syngest.com/ for near fossil free agriculture. They "note research that has just come to light from ARS, determining that farmers can provide for their own farm-based fuel needs by devoting roughly 5-7 percent of their land to bioenergy production. Produced at cost, we believe that channel, combined with the existing mandates which utilize feedstocks sources developed for the commercial market (such as brown and yellow grease, and energy crops), represent the near-terms “wins” for biodiesel. Farmers utilize an estimated 1 billion gallons of diesel fuel picking up the US corn and soy harvest – B100 used for this channel, and roughly B2 for the general market, would give biodiesel a very big push, and in the mid-term we may well see revolutions in feedstock availability from the likes of algae and new oilseeds crops to advance the story even farther." http://biofuelsdigest.com/bdigest/2011/02/07/biodiesel-roars-back-with-mandate-tax-credits-b20-oks/ The Digest story gives an error link for more information, I searched around ARS, but couldn't find the referenced ARS study. Cheers to someone who can, Erich

Erich Knight wrote: 02-17-2011 18:46:38

Biomass should never be just burnt, instead it should be fractionated to it's high value uses. Biochar systems achieve this, to fill in gaps and hopefully expand your story & research , particularly concerning Christoph Steiner's new work with Biochar and NH3 conservation in composting systems. Recent NATURE STUDY; Sustainable bio char to mitigate global climate change http://www.nature.com/ncomms/journal/v1/n5/full/ncomms1053.html Not talked about in this otherwise comprehensive study are the climate and whole ecological implications of new , higher value, applications of chars. First, the in situ remediation of a vast variety of toxic agents in soils and sediments. Biochar Sorption of Contaminants; http://www.biorenew.iastate.edu/events/biochar2010/conference-agenda/agenda-overview/breakout-session-5/agriculture-forestry-soil-science-and-environment.html Dr. Lima's work; Specialized Characterization Methods for Biochar http://www.biorenew.iastate.edu/events/biochar2010/conference-agenda/agenda-overview/breakout-session-4/production-and-characterization.html And at USDA; The Ultimate Trash To Treasure: *ARS Research Turns Poultry Waste into Toxin-grabbing Char http://www.ars.usda.gov/IS/AR/archive/jul05/char0705.htm Second, The uses as a feed ration for livestock to reduce GHG emissions and increase disease resistance. Third, Recent work by C. Steiner, at U of GA, showing a 52% reduction of NH3 loss when char is used as a composting accelerator. This will have profound value added consequences for the commercial composting industry by reduction of their GHG emissions and the sale of compost as a nitrogen fertilizer. Since we have filled the air , filling the seas to full, Soil is the Only Beneficial place left. Carbon to the Soil, the only ubiquitous and economic place to put it. Thanks for your efforts. Erich Erich J. Knight Chairman; Markets and Business Committee 2010 US BiocharConference, at Iowa State University http://www.biorenew.iastate.edu/events/biochar2010/conference-agenda/agenda-overview.html EcoTechnologies Group Technical Adviser http://www.ecotechnologies.com/index.html Shenandoah Gardens (Owner) 1047 Dave Barry Rd. McGaheysville, VA. 22840 540 289 9750 Co-Administrator, Biochar Data base & Discussion list TP-REPP