Uranium enrichment

| Topics: |

This EOE article is adapted from an information paper published by the World Nuclear Association (WNA). WNA information papers are frequently updated, so for greater detail or more up to date numbers, please see the latest version on WNA website (link at end of article).

- Most of the 470 commercial nuclear power reactors operating or under construction in the world today require uranium 'enriched' in the U-235 isotope for their fuel.

- Two commercial processes are employed for this enrichment. Another process based on laser excitation is under development in Australia and USA.

- Prior to enrichment, uranium oxide must be converted to a fluoride.

Contents

Introduction

Uranium (Uranium enrichment) found in nature consists largely of two isotopes, uranium-235 (235U) and uranium-238 (238U). The production of energy in nuclear reactors is from the 'fission' or splitting of the 235U atoms, a process which releases energy in the form of heat. 235U is the main fissile isotope of uranium.

Natural uranium contains 0.7% of the U-235 isotope. The remaining 99.3% is mostly the U-238 isotope, which does not contribute directly to the fission process (though it does so indirectly by the formation of fissile isotopes of plutonium).

235U and 238U are chemically identical, but differ in their physical properties, particularly their mass. The nucleus of the 235U atom contains 92 protons and 143 neutrons, giving an atomic mass of 235 units. The 238U nucleus also has 92 protons but has 146 neutrons—three more than 235U, and therefore has a mass of 238 units.

The difference in mass between 235U and 238U allows the isotopes to be separated and makes it possible to increase or "enrich" the percentage of 235U. All present enrichment processes, directly or indirectly, make use of this small mass difference.

Some reactors, for example the Canadian-designed Candu and the British Magnox reactors, use natural uranium as their fuel. Most present day reactors (Light water reactors or LWRs) use enriched uranium where the proportion of the 235U isotope has been increased from 0.7% to about 3 or up to 5%. (For comparison, uranium used for nuclear weapons would have to be enriched in plants specially designed to produce at least 90% 235U.)

International enrichment centres

Following proposals from the International Atomic Energy Agency (IAEA) and Russia, and in connection with the US-led Global Nuclear Energy Partnership (GNEP), there are moves to establish international uranium enrichment centres.

The first of these is the Angarsk IUEC in Siberia, with Kazakh and Ukrainian equity. The French Atomic Energy Commission has proposed that the new Georges Besse II plant in France be open to international partnerships on a similar basis, and a further proposal seems likely for South Africa.

The main issue however is technology transfer, and the host country's and equity holders' access to the actual technology. Urenco (owned by three governments - UK, Netherlands, Germany) and Russia have made it plain that if their technology is used in such centres it will not be accessible either to hosts or other equity holders.

Conversion

Uranium leaves the mine as the concentrate of a stable oxide known as U3O8 or as a peroxide,. It still contains some impurities, and prior to enrichment has to be further refined before being converted to uranium hexafluoride (UF6), commonly referred to as `hex'.

Conversion plants are operating commercially in USA, Canada, France, UK and Russia.

Conversion of uranium oxide to UF6 is achieved by a dry fluoride volatility process in the USA, while all other converters use a wet process.

World Conversion supply and demand (thousand tonnes U as UF6)

| Supplier |

2007 | 2010 | 2015 |

| Cameco (Canada & UK) |

13.7 | 15.5 | 15.5 |

| Areva | 14.0 |

14.0 | 15.0 |

| ConverDyn | 12.0 | 14.0 | 18.0 |

| Rosatom | 5.0 | 5.5 | 10.0 |

| China | 1.5 | 2.5 | 2.5 |

| UF6e inventories | 20.1 | 20.8 | 11.0 |

| Total Supply |

66.3 | 72.3 | 72.0 |

| Requirements (EDI) |

59 | 62-65 | 67-77 |

| Requirements (WNA) |

61 | 61-64 | 70-77 |

Source: Julian Steyn, EDI, Nuclear Engineering International Sept 2007 (except last row)

A different breakdown of 2007 conversion capacity is provided in the 2007 Euratom Aunnual Report:

| Company |

Capacity (thousand tonnes U) |

| Cameco | 19.26 |

| Atomenergoprom | 17.76 |

| Areva | 16.5 |

| Converdyn | 13.0 |

| CNNC | 1.0 |

| Nukem | 0.92 |

| World Total |

68.44 |

After initial refining, which may involve the production of uranyl nitrate, uranium trioxide is reduced in a kiln by hydrogen to uranium dioxide. This is then reacted in another kiln with hydrogen fluoride (HF) to form uranium tetrafluoride (UF4). The tetrafluoride is then fed into a fluidized bed reactor with gaseous fluorine to produce UF6. The alternative wet process involves making the UF4 from UO2 by a wet process, using aqueous HF.

The UF6, particularly if moist, is highly corrosive. When warm it is a gas, suitable for use in the enrichment process. At lower temperature and under moderate pressure, the UF6 can be liquefied. The liquid is run into specially designed steel shipping cylinders which are thick walled and weigh over 15 tonnes when full. As it cools, the liquid UF6 within the cylinder becomes a white crystalline solid and is shipped in this form.

The siting, environmental and security management of a conversion plant is subject to the regulations that are in effect for any chemical processing plant involving fluorine-based chemicals.

Enrichment

A number of enrichment processes have been demonstrated historically or in the laboratory, but only two, the gaseous diffusion process and the gas centrifuge process, are operating on a commercial scale. In both of these, UF6 gas is used as the feed material. Molecules of UF6 with 235U atoms are about one percent lighter than the rest, and this difference in mass is the basis of both processes. Isotope separation is a physical process. [1]

Large commercial enrichment plants are in operation in France, Germany, Netherlands, UK, USA, and Russia, with smaller plants elsewhere. New centrifuge plants are being built in France and USA.

World Enrichment capacity (thousand SWU/yr)

| 2002 | 2006 | 2015 | |

| France - Areva |

10,800* | 10,800* | 7,500 |

| Germany-Netherlands-UK - Urenco |

5,850 | 9,000 | 15,000 |

| Japan - JNFL |

900 | 1,050 | 1,500 |

| USA - USEC |

8,000* | 8,000* | 3,500+ |

| USA - Urenco |

0 | 0 | 3,000 |

| USA - Areya |

0 | 0 | 1,000 |

| Russia - Tenex | 20,000 | 25,000 | 33,000+ |

| China - CNNC |

1,000 | 1,000 | 2,000 |

| Other | 5 | 300 | 300 |

| total | 46,500 approx |

54,150 | 66,800 |

| Requirements (WNA) | 48,428 | 57,000 - 63,000 |

Source: OECD NEA (2003), Nuclear Energy Data; Nuclear Engineering International (2003), World Nuclear Handbook, USEC, WNA Market Report 2007

- diffusion ** Urenco reached 10,000 in June 2008. Including the US plant it expects to reach 15,000 in 2012

The capacity of enrichment plants is measured in terms of 'separative work units' or SWU. The SWU is a complex unit which is a function of the amount of uranium processed and the degree to which it is enriched (i.e., the extent of increase in the concentration of the 235U isotope relative to the remainder) and the level of depletion of the remainder. The unit is strictly: Kilogram Separative Work Unit, and it measures the quantity of separative work performed to enrich a given amount of uranium a certain amount. It is thus indicative of energy used in enrichment when feed and product quantities are expressed in kilograms. The unit 'tonnes SWU' is also used.

For instance, to produce one kilogram of uranium enriched to 3% 235U requires 3.8 SWU if the plant is operated at a tails assay 0.25%, or 5.0 SWU if the tails assay is 0.15% (thereby requiring only 5.1 kg instead of 6.0 kg of natural uranium feed).

About 100-120,000 SWU is required to enrich the annual fuel loading for a typical 1000 MWe light water reactor. Enrichment costs are substantially related to electrical energy used. The gaseous diffusion process consumes about 2500 kWh (9000 MJ) per SWU, while modern gas centrifuge plants require only about 50 kWh (180 MJ) per SWU.

Enrichment accounts for almost half of the cost of nuclear fuel and about 5% of the total cost of the electricity generated. It can also account for the main greenhouse gas impact from the nuclear fuel cycle if the electricity used for enrichment is generated from coal. However, it still only amounts to 0.1% of the carbon dioxide from equivalent coal-fired electricity generation if modern gas centrifuge plants are used, or up to 3% in a worst case situation.

The trend in enrichment technology is to retire obsolete diffusion plants:

| Supply source: |

2007 |

2017 |

| Diffusion | 25% | 0 |

| Centrifuge | 65% | 96% |

| HEU ex weapons |

10% | 4 |

Gaseous diffusion process

Commercial uranium enrichment was first carried out by the diffusion process in the USA. It has since been used in Russia, UK, France, China and Argentina as well. Today, only the USA and France use the process on any significant scale. The remaining large USEC plant in the USA was originally developed for weapons programs and has a capacity of some 8 million SWU per year. At Tricastin, in southern France, a more modern diffusion plant with a capacity of 10.8 million kg SWU per year has been operating since 1979 (see photo at left). This plant can produce enough 3.7% enriched uranium a year to fuel some ninety 1000 MWe nuclear reactors.

At present, the gaseous diffusion process accounts for about 40% of world enrichment capacity. However, though they have proved durable and reliable, most gaseous diffusion plants are now nearing the end of their design life and the focus is on centrifuge enrichment technology, which is replacing them.

The diffusion process involves forcing uranium hexafluoride gas under pressure through a series of porous membranes or diaphragms. As uranium-235 molecules are lighter than the uranium-238 molecules, they move faster and have a slightly better chance of passing through the pores in the membrane. The UF6 diffuses through the membrane and is thus slightly enriched, while the gas that did not pass through is depleted in 235U.

This process is repeated many times in a series of diffusion stages called a cascade. Each stage consists of a compressor, a diffuser and a heat exchanger to remove the heat of compression. The enriched UF6 product is withdrawn from one end of the cascade and the depleted UF6 is removed at the other end. The gas must be processed through some 1400 stages to obtain a product with a concentration of 3% to 4% uranium-235.

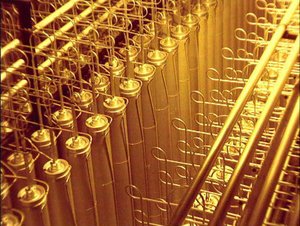

Centrifuge process

The gas centrifuge process was first demonstrated in the 1940s but was shelved in favor of the simpler diffusion process. It was then developed and brought on stream in the 1960s as the second-generation enrichment technology. It is economic on a smaller scale, e.g., under 2 million SWU/yr, which enables staged development of larger plants. It has been deployed at a commercial level in Russia and in Europe by Urenco, an industrial group formed by British, German and Dutch companies. Russia¹s four plants at Seversk, Zelenogorsk, Angarsk and Novouralsk account for some 40% of world capacity. Urenco operates enrichment plants in UK, Netherlands and Germany and is participating in a proposal for one in the USA.

In Japan, JNC and JNFL operate small centrifuge plants, the capacity of JNFL's at Rokkasho was planned to be 1.5 million SWU/yr. China also has a small centrifuge plant imported from Russia at Lanzhou, which is expected to reach 0.5 million SWU/yr about 2005. China has two small centrifuge plants imported from Russia. One at Lanzhou is 0.5 million SWU/yr and the other main one at Hanzhun is operating at 0.5 million SWU/yr and is being doubled in size. Brazil has a small plant which is being developed to 0.2 million SWU/yr. Pakistan has developed centrifuge enrichment technology, and this appears to have been sold to North Korea. Iran has sophisticated centrifuge technology which is being commissioned from 2008.

Both France and the USA are now considering centrifuge technology to replace their ageing diffusion plants, not least because they are more economical to operate. As noted, a centrifuge plant requires as little as 50 kWh/SWU power (Urenco at Capenhurst, UK input 62.3 kWh/SWU for the whole plant in 2001-02, including infrastructure and capital works).

The EUR 3 billion French plant operated by Areva - Georges Besse II - is expected to start commercial operation in 2009 and ramp up to full capacity of 7.5 million SWU/yr in 2018.

The $1.5 billion National Enrichment Facility in New Mexico, USA will use the same 6th generation Urenco technology and first production is expected in 2008, with full capacity of 3 million SWU/yr being reached in 2013.

Following this, Areva is building a $2 billion, 3 million SWU/yr plant at Idaho Falls, USA which it expects to commence operation in 2014, ramping up to full production in 2019.

USEC is building its American Centrifuge Plant in Piketon, Ohio, on the same Portsmouth site where the DOE's experimental plant operated in the 1980s, involving 1300 centrifuges as the culmination of a very major R&D program. The Lead Cascade demonstration plant started operation in September 2007. For the main centrifuge plant initial annual capacity of 3.8 million SWU from 2012 is envisaged, costing $3.5 billion, though its licence application is for 7 million SWU to allow for expansion. Authorisation for enrichment up to 10% was sought - most enrichment plants operate up to 5% U-235 product, which is becoming a serious constraint as reactor fuel burnup increases.

Like the diffusion process, the centrifuge process uses UF6 gas as its feed and makes use of the slight difference in mass between uranium-235 and uranium-238. The gas is fed into a series of vacuum tubes, each containing a rotor one to two meters long and 15-20 cm diameter. When the rotors are spun rapidly, at 50,000 to 70,000 rpm, the heavier molecules with 238U increase in concentration towards the cylinder's outer edge. There is a corresponding increase in concentration of 235U molecules near the center. These concentration changes are enhanced by inducing the gas to circulate axially within the cylinder.

The enriched gas forms part of the feed for the next stages while the depleted UF6 gas goes back to the previous stage. Eventually, enriched and depleted uranium are drawn from the cascade at the desired assays. To obtain efficient separation of the two isotopes, centrifuges rotate at very high speeds, with the outer wall of the spinning cylinder moving at between 400 and 500 meters per second to give a million times the acceleration of gravity.

Although the capacity of a single centrifuge is much smaller than that of a single diffusion stage, its capability to separate isotopes is much greater. Centrifuge stages normally consist of a large number of centrifuges in parallel. Such stages are then arranged in cascade similarly to those for diffusion. In the centrifuge process, however, the number of stages may only be 10 to 20, instead of a thousand or more for diffusion.

Laser processes

Laser enrichment processes have been the focus of interest for some time. They are a possible third-generation technology promising lower energy inputs, lower capital costs and lower tails assays, hence significant economic advantages. None of these processes is yet ready for commercial use, though one is well advanced.

Development of the Atomic Vapor Laser Isotope Separation (AVLIS, and the French SILVA) began in the 1970s. In 1985, the US Government backed it as the new technology to replace its gaseous diffusion plants as they reached the end of their economic lives early in the 21st century. However, after some US$2 billion in research and development, it was abandoned in the US in favor of SILEX, a molecular process. French work on SILVA has now ceased, following a 4-year program to 2003 to prove the scientific and technical feasibility of the process. Some 200kg of 2.5% enriched uranium was produced by this process.

Atomic vapor processes work on the principle of photo-ionization, whereby a powerful laser is used to ionize particular atoms present in a vapor of uranium metal. An electron can be ejected from an atom by light of a certain frequency. The laser techniques for uranium use frequencies which are tuned to ionize a uranium-235 atom but not a uranium-238 atom.) The positively-charged 235U ions are then attracted to a negatively-charged plate and collected. Atomic laser techniques may also separate plutonium isotopes.

The main molecular processes that have been researched work on a principle of photo-dissociation of UF6 to solid UF5, using tuned laser radiation as above and breaking the molecular bond holding the sixth fluorine atom. This then enables the UF5 to be separated from the unaffected UF6 molecules containing U-238 atoms, hence achieving a separation of isotopes. Any process using UF6 fits more readily within the conventional fuel cycle than the atomic process.

The only remaining laser process on the world stage is SILEX, an Australian development which is molecular and utilizes UF6. In 1996, the United States Enrichment Corporation (USEC) secured the rights to evaluate and develop SILEX for uranium but relinquished these in 2003.

In 2006, GE Energy entered a partnership to develop the SILEX process. It provided for GE (now GE-Hitachi) to construct in the USA an engineering-scale test loop (by the end of 2008) then a pilot plant or lead cascade, which could be operating by 2012, and expanded to a full commercial plant. Apart from US$20 million upfront and subsequent payments, the license agreement will yield 7-12% royalties, the precise amount depending on how low the cost of deploying the commercial technology. GE referred to SILEX, which it has re-badged as Global Laser Enrichment (GLE), as "game-changing technology" with a "very high likelihood" of success. In August 2007 Silex confirmed that GE-Hitachi planned "to complete the test loop program at the end of 2008, which if successful, would open the way for the first commercial enrichment plant to be constructed." In mid 2008 Cameco bought into the GLE project, paying $124 million for 24% share, alongside GE (51%) and Hitachi (25%).

In October 2007 the two largest US nuclear utilities, Exelon and Entergy, signed letters of intent to contract for uranium enrichment services from GLE. The utilities may also provide GLE with facility licensing and public acceptance support if needed for development of a commercial-scale GLE plant. GEH has begun preparing a GLE test loop at Global Nuclear Fuel's Wilmington, North Carolina fuel fabrication facility - GNF is a partnership of GE, Toshiba, and Hitachi. Before moving ahead with full-scale production plans, GEH will first evaluate results of the testing. Preparations for licensing a commercial plant at Wilmington, North Carolina, envisage a start-up date of 2012, with annual capacity of 3.5 to 6 million separative work units (SWU). In January 2009 GEH submitted the first part of its licence application for the Wilmington enrichment plant.

Applications to silicon and zirconium are also being developed by Silex Systems near Sydney.

Electromagnetic process

A very early endeavour was the electromagnetic isotope separation (EMIS) process. This was developed in the early 1940s in the Manhattan Project to make the highly enriched uranium used in the Hiroshima bomb, but was abandoned soon afterwards. However, it reappeared as the main thrust of Iraq's clandestine uranium enrichment program for weapons discovered in 1992. EMIS uses the same principles as a mass spectrometer (albeit on a much larger scale). Ions of uranium-238 and uranium-235 are separated because they describe arcs of different radii when they move through a magnetic field. The process is very energy-intensive - about ten times that of diffusion.

Aerodynamic processes

Two aerodynamic processes were brought to demonstration stage around the 1970s. One is the jet nozzle process, with demonstration plant built in Brazil, and the other the Helikon vortex tube process developed in South Africa. Neither is in use now, though the latter is the forerunner of new R&D. They depend on a high-speed gas stream bearing the UF6 being made to turn through a very small radius, causing a pressure gradient similar to that in a centrifuge. The light fraction can be extracted towards the centre and the heavy fraction on the outside. Thousands of stages are required to produce enriched product for a reactor. Both processes are energy-intensive - over 3000 kWh/SWU. The Helikon Z-plant in the early 1980s was not commercially oriented and had less than 500,000 SWU/yr capacity. It required some 10,000 kWh/SWU.

The Aerodynamic Separation Process (ASP) being developed by Klydon in South Africa employs similar stationary-wall centrifuges with UF6 injected tangentially. It is based on Helikon but pending regulatory authorisation it has not yet been tested on UF6 – only light isotopes such as silicon. However, extrapolating from results there it is expected to have an enrichment factor in each unit of 1.10 (cf 1.03 in Helikon) with about 1000 kWh/SWU and development of it is aiming for 1.15 enrichment factor and less than 500 kWh/SWU. Projections give an enrichment cost under $100/SWU, with this split evenly among capital, operation and energy input.

Enrichment of reprocessed uranium

In some countries used fuel is reprocessed to recover its uranium and plutonium, and to reduce the final volume of high-level wastes (HLW). The plutonium is normally recycled promptly into mixed-oxide (MOX) fuel, by mixing it with depleted uranium.

Where uranium recovered from reprocessing used nuclear fuel (RepU) is to be re-used, it needs to be converted and re-enriched. This is complicated by the presence of impurities and two new isotopes in particular: U-232 and U-236, formed by or following neutron capture in the reactor, and increase with higher burn-up levels. U-232 is largely a decay product of Pu-236, and increases with storage time in used fuel, peaking at about ten years. Both decay much more rapidly than uranium-235 and uranium-238, and one of the daughter products of 232U emits very strong gamma radiation, which means that shielding is necessary in the plant handling material with more than very small traces of it. U-236 is a neutron absorber, which impedes the chain reaction, and means that a higher level of 235U enrichment is required in the product to compensate. Being lighter, both isotopes tend to concentrate in the enriched (rather than depleted) output, so reprocessed uranium which is re-enriched for fuel must be segregated from enriched fresh uranium. The presence of U-236 in particular means that most reprocessed uranium can be recycled only once - the main exception being in the UK with AGR fuel made from recycled Magnox uranium being reprocessed.

All these considerations mean that only RepU from low-enriched, low-burnup used fuel is normally recycled directly through an enrichment plant. For instance, some 16,000 tonnes of RepU from Magnox reactors [2] in UK has been used to make about 1650 tonnes of enriched AGR fuel, via two enrichment plants. Much smaller quantities have been used elsewhere, in France and Japan. Some re-enrichment, eg for Swiss, German and Russian fuel, is actually done by blending RepU with HEU.

A laser process would theoretically be ideal for enriching RepU as it would ignore all but the desired U-235, but this remains to be demonstrated with reprocessed feed.

After enrichment

The enriched UF6 is converted to UO2 and made into fuel pellets—ultimately a sintered ceramic—that are encased in metal tubes to form fuel rods, typically up to four meters long. A number of fuel rods make up a fuel assembly, which is ready to be loaded into the nuclear reactor.

Depleted Uranium and Deconversion

Depleted uranium (DU) is stored long-term as UF6 or preferably, after deconversion, as U3O8, allowing HF to be recycled. To early 2007, about one quarter of the 1.2 million tonnes of DU had been deconverted.

The main deconversion plant is run by Areva NC at Tricastin, France. This is essentially a dry process, with no liquid effluent, and is the same as that used for the enriched portion, albeit at a scale of 20,000 tonnes per year in the one plant.

The UF6 is first vapourised in autoclaves with steam, then the uranyl fluoride is reacted with hydrogen at 700ºC to yield an HF byproduct for sale and U3O8 powder which is packed into 10-tonne containers for storage.

3UO2F2 + 2H2O + H2? U3O8 + 6HF

Ownership title of DU is normally transferred to the enricher as part of the commercial deal. At present the only deconversion plant is in France, but others are planned. It is sometimes considered as a waste, but usually it is understood as a long-term strategic resource which can be used in a future generation of fast neutron reactors. Any much more efficient enrichment process would also make it into an immediately usable resource as source of more U-235.

Environmental Issues

With the minor exception of reprocessed uranium, enrichment involves only natural, long-lived radioactive materials; there is no formation of fission products or irradiation of materials, as in a nuclear reactor. Feed, product, and depleted material are all in the form of UF6, though the depleted uranium may be stored long-term as the more stable U3O8.

Uranium is only weakly radioactive, and its chemical toxicity—especially as UF6—is more significant than its radiological toxicity. The protective measures required for an enrichment plant are therefore similar to those taken by other chemical industries concerned with the production of fluorinated chemicals.

Uranium hexafluoride forms a corrosive material (HF - hydrofluoric acid) when exposed to moisture, therefore any leakage is undesirable. Hence:

- in almost all areas of a centrifuge plant, the pressure of the UF6 gas is maintained below atmospheric pressure and thus any leakage could only result in an inward flow;

- double containment is provided for those few areas where higher pressures are required; and

- effluent and venting gases are collected and appropriately treated.

Notes

<!--[if!supportFootnotes]-->^ One chemical process has been demonstrated to pilot plant stage but not used. The French Chemex process exploited a very slight difference in the two isotopes' propensity to change valency in oxidation/reduction, utilising aqueous (III valency) and organic (IV) phases. (Uranium enrichment)

Further Reading

- WNA paper on Uranium enrichment

- Heriot, I.D. (1988). Uranium Enrichment by Centrifuge, Report EUR 11486, Commission of the European Communities, Brussels.

- IAEA 2007, Management of Reprocessed Uranium - current status and future prospects, Tec doc 1529.

- Kehoe, R.B. (2002). The Enriching Troika, a History of Urenco to the Year 2000. Urenco, Marlow UK.

- Wilson, P.D. (ed)(1996). The Nuclear Fuel Cycle - from ore to wastes. Oxford University Press, Oxford UK.