Skimmers (Water)

Skimmers

The common name used for various oil recovery units is oil skimmer or simply skimmer. A skimmer is defined as any mechanical device specifically designed for the removal of oil (or oil/water mixture) from the surface of water without altering the water’s physical and/or chemical characteristics. The principles for skimmers’ operation are based on the fluidity properties of oil and oil/water mixture, density differences between oil or oil/water mixtures, and water or differences in adhesion to materials. Skimmers are often deployed in combination with oil containment booms, which are temporary floating barriers used to contain the oil by concentrating it into thicker surface layers. These devices are constructed of weather and water resistant materials such as stainless steel, rubber, aluminum and polypropylene. Skimmers are directed to oily areas by pilots flying over designated areas.

Skimmers have proven an essential tool in addressing the Deepwater Horizon oil spill in the Gulf of Mexico. Designed to recover oil from land or water, these oil collection devices come in a variety of sizes and forms. Currently, skimmers are being used throughout Louisiana, Mississippi, Alabama and the Florida Panhandle.

Skimmer Components

- Skimming head – the component separating oil from water

- Transfer system – built in pump or vacuum unit, discs, brushes, belts or ropes, hoses and couplings

- Containment unit – Tank or container for recovered oil

Three factors normally used to describe skimmer performance

- Recovery Rate is the rate at which pure oil is being recovered

- Recovery Efficiency is the relation between recovered oil and recovered fluids (oil/water mixture)

- Throughput Efficiency is the relation between recovered oil and encountered oil.

Skimmer Types

Disk skimmer. Skimming systems have equipment to mechanically remove oil floating on the surface of the water. The skimmed oil is transferred to a storage area, often a barge. Credit: Alaska DEC Disk skimmer. Skimming systems have equipment to mechanically remove oil floating on the surface of the water. The skimmed oil is transferred to a storage area, often a barge. Credit: Alaska DEC

|

Skimmers vary considerably in their working principles and construction. The method of collecting the oil is normally used to distinguish between skimmers and their respective uses.

Weir Skimmers

Weir skimmers include any device using gravity to drain oil from the water surface. A free floater, weirs are normally launched from a vessel, using a crane, and are guided by ropes. The edge of the weir is positioned just below the upper slick surface allowing oil to flow over the weir edge into a collecting sump and then to be pumped to storage. It is probably the most commonly used skimmer type because of its simple construction. Weir systems can either be remote controlled or self-adjusting. Remote adjusting systems are based on compressed air.

Vacuum Skimmers

Vacuum skimmers do not have a pump incorporated in the actual floating skimmer device. This device is normally called a skimmer head. The recovered oil/water mixture is sucked from the skimmer head by a suction or vacuum pump. The simplest type of vacuum skimmer is a hose directly connected to a vacuum truck, which can easily be employed in harbors or rivers. Vacuum skimmers are restricted to use in harbors and calm waters as they are very sensitive to waves.

Oleophilic Skimmers

Oleophilic skimmers recover oil based on specific materials which have greater affinity for oil than for water. Such materials are known as oleophilic (mops, rope, brushes or discs). The moving part of the skimmer (rope, belt, drum and disc) with the oleophilic surface is rotated or drawn through the oil slick. The oil is then scraped or squeezed off and guided into a sump to be pumped or sucked away.

Oleophilic skimmers are divided into subgroups: Disc Skimmers, Rope Mop Skimmers, Belt Skimmers, Brush Skimmers

Brush and Belt Skimmers

Brush and Belt skimmers are large and either mounted on a barge (self-floating unit) or on a specially constructed vessel. Deploying large skimmers can be complicated and requires heavy equipment and specially trained personnel. These skimmers have a high recovery efficiency and a good recovery rate, but are specialized products.

Vertical Rope Mop Skimmers

Vertical Rope Mop skimmers are large units launched from a vessel or shore using a crane during the entire operation. The vertical rope mop skimmer is normally used for single sweep operations only. This skimmer type is not sensitive to waves. Very little water is collected during recovery which makes this type of skimmer suitable for lighter oil types. Oil is wrung out of the mop ropes and stored in a collection sump on board the vessel; debris will not affect the pump operation.

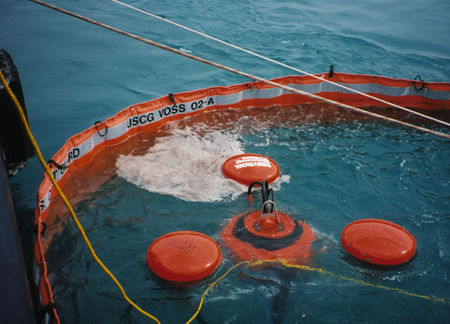

Disc Skimmers

Disc skimmers have recovery capacities from 40-100 m3/h and can be used for open sea operations. Disc skimmers work best with lighter types of oil (medium viscosity) and cannot handle emulsified oil. The volume and weight of these discs is quite large due to the size and number of rotating discs. Crane operators deploy, guide and control the heavy disc skimmers.

Deployment and Use of Skimmers for On-Shore Operations

Spills on Soil

The DEMSI 250 skimmers, outriggers and oil-collection booms are deployed in Western Lake Erie. Credit: U.S. Coast Guard The DEMSI 250 skimmers, outriggers and oil-collection booms are deployed in Western Lake Erie. Credit: U.S. Coast Guard

|

For oil spills on soil, the best solution is digging a pit at a collection point and guiding the oil towards the pit. A vacuum skimmer can be used for recovery of oil from the pit. It may be necessary to mechanically remove the top soil for further treatment using an excavator or shovels.

Spills on Concrete, Asphalt or other hard surface

To avoid further spreading of the oil, sorbent booms can be laid out to contain the spill (Oil spill). If the oil is fresh, it can be recovered using a vacuum skimmer. If the oil is not fresh (solidified), high pressure cleaners combined with chemical treatment is an option.

Shallow water areas (marsh, swamp or lagoons)

Sorbent booms can be used to guide the oil towards the skimmer. Skimmers could be rope mop or disc skimmers, since there might be a high content of debris in the water. If it is not possible to concentrate the spilled oil, rope mop skimmers can be used to cover a larger area than the disc skimmer. Any type of mechanical treatment in sensitive areas, such as marsh or shallow water, should be avoided where possible; heavy equipment will damage the environment much more than the smaller skimming recovery devices.