Mixed oxide fuel (MOX)

| Topics: |

This EOE article is adapted from an information paper published by the World Nuclear Association (WNA). WNA information papers are frequently updated, so for greater detail or more up to date numbers, please see the latest version on WNA website (link at end of article).

Contents

Introduction

In every nuclear reactor there is both fission of isotopes such as uranium-235 (235U), and the formation of new, heavier isotopes due to neutron capture, primarily by uranium-238 (238U). Most of the fuel mass in a reactor is 238U. This can become plutonium-239 (239Pu) and by successive neutron capture 240Pu, 241Pu and 242Pu as well as other transuranic or actinide isotopes. 239Pu and 241Pu are fissile, like 235U. Very small quantities of 236Pu and 238Pu are formed similarly from 235U. Normally, with the fuel being changed every three years or so, about half of the 239Pu is "burned" in the reactor, providing about one-third of the total energy (Mixed oxide fuel (MOX)) . It behaves like 235U and its fission releases a similar amount of energy. The higher the burn-up, the less fissile plutonium remains in the used fuel. Typically, about one percent of the used fuel discharged from a reactor is plutonium, and some two-thirds of this is fissile (~ 50% 239, 15% 241Pu). Worldwide, some 70 tonnes of plutonium contained in spent fuel arises each year.

A single recycle of plutonium in the form of mixed oxide fuel (MOX) increases the energy derived from the original uranium by some 12%, and if the uranium is also recycled this becomes about 22%. (Based on light water reactor fuel with burn-up of 45 GWd/tU. Lower burn-up will leave more U-235 and hence give a greater saving by recycle.)

Today there is a significant amount of separated uranium and plutonium which may be recycled. It is equivalent to about three years supply of natural uranium from world mines.

Inventory of Separated Recyclable Materials (NEA 2007)

| quantity (tonnes) |

Natural uranium equivalent (tonnes) | |

| Plutonium from reprocessed fuel | 320 | 60,000 |

| Uranium from reprocessed fuel | 45,000 | 50,000 |

| Ex-military plutonium | 70 | 15,000 |

| Ex-military high-enriched uranium | 230 | 70,000 |

In addition, there is about 1.6 million tonnes of enrichment tails, with recoverable fissile uranium.

Recycling Uranium Fuel

The first step in recycling fuel is separating the plutonium from the remaining uranium (about 96% of the spent fuel) and the fission products with other wastes (together about 3%). Then the plutonium needs to be separated from most or all of the uranium. All this is undertaken at a reprocessing plant.

The plutonium, as an oxide, is then mixed with depleted uranium left over from an enrichment plant to form fresh mixed oxide fuel (MOX, which is UO2+PuO2). MOX fuel, consisting of about 7-9% plutonium mixed with depleted uranium, is equivalent to uranium oxide fuel enriched to about 4.5% 235U, assuming that the plutonium has about two-thirds fissile isotopes. If weapons-grade plutonium were used (>90% 239Pu), only about 5% plutonium would be needed in the mix.

Plutonium from reprocessed UO2 fuel is usually fabricated into MOX as soon as possible to avoid problems with the decay of short-lived plutonium isotopes. In particular, 241Pu (half-life 14 years) decays to americium-241 (241Am), a strong gamma ray emitter, giving rise to a potential occupational health hazard if separated plutonium over five years old is used in a normal MOX plant. The 241Am level in stored plutonium increases about 0.5% per year, with corresponding decrease in fissile value of the plutonium. 238Pu (half-life 88 years) is increased in high-burnup fuel. It is a strong alpha ray emitter and a source of spontaneous neutrons. 239Pu, 240Pu and 242Pu are long-lived and hence little-changed with prolonged storage. (see also paper on plutonium)

Reprocessing of 850 tonnes of French used fuel per year (about 15 years after discharge) produces 8.5 tonnes of plutonium (immediately recycled as 100 tonnes of MOX) and 810 tonnes of reprocessed uranium (RepU). Of this about two thirds is converted into stable oxide form for storage. One third of the RepU is re-enriched and EdF has demonstrated its use in 900 MWe power reactors.

Fast neutron reactors allow multiple [[recycling]s] of plutonium, since all transuranic isotopes there are fissionable, but in thermal reactors isotopic degradation limits the plutonium recycling potential and most spent MOX fuel is stored pending the deployment of more effective fast reactors. The plutonium isotopic composition of used MOX fuel at 45 GWd/tU burnup is about 37% 239Pu, 32% 240Pu, 16% 241Pu, 12% 242Pu and 4% 238Pu.

In 2007 EdF said that the plutonium stored at La Hague from reprocessing could provide the start-up fuel for seven Generation IV fast reactors, with 15 tonnes for each (the French inventory of separated plutonium at the end of 2006 was 49 tonnes, Russia had 41 tonnes). The UK had 77 tonnes at the end of 2007.

(Recycled uranium from a reprocessing plant is re-enriched on its own for use as fresh fuel. Because it contains some neutron-absorbing 234U and 236U, the enrichment level is slightly greater than for mined uranium providing an equivalent fuel source.)

MOX Use

MOX was first used in a thermal reactor in 1963, but did not come into commercial use until the 1980s.So far about 2000 tonnes of MOX fuel has been fabricated and loaded into power reactors. In 2006 about 180 tonnes of MOX fuel was loaded into over 30 reactors (mostly PWR) Europe.

Today, MOX is widely used in Europe and is planned for future use in Japan. Currently over 40 reactors in Europe (Belgium, Switzerland, Germany and France) are licensed to use MOX and over 30 are doing so. Japan also plans to use MOX in up to 20 of its nuclear reactors. Most reactors use it as about one-third of their core, but some will accept up to 50% MOX assemblies. France aims to have all its 900 MWe series of reactors running with at least one-third MOX in the future. Japan aims to have one-third of its reactors using MOX by 2010, and has approved construction of a new reactor with a complete fuel loading of MOX. Advanced light water reactors, such as the European Pressurized Water Reactor (EPR) or Westinghouse Electric Company's AP1000, will be able to accept complete fuel loadings of MOX.

The use of up to 50% of MOX does not change the operating characteristics of a reactor, though the plant must be designed or adapted slightly to allow for its use. For example, more control rods are needed, and for more than 50% MOX loading, significant changes are necessary and a reactor must be designed accordingly.

An advantage of powering a nuclear reactor with MOX is that the fissile concentration of the fuel can be increased easily by adding a bit more plutonium, whereas enriching uranium to higher levels of 235U is relatively expensive. As reactor operators seek to burn fuel harder and longer, increasing burnup from around 30,000 MW days per tonne a few years ago to over 50,000 MWd/t now, MOX use becomes more attractive.

When uranium prices were low, reprocessing to separate plutonium for recycle as MOX was not itself economic, but with the rise in uranium prices coupled with reducing the volume of spent fuel to be managed, it is becoming so. Seven UO2 fuel assemblies give rise to one MOX assembly, as well as vitrified high-level waste, resulting in only about 35% of the volume, mass and cost of disposal.

MOX Production

Two plants currently produce commercial quantities of MOX fuel - in France and UK. In 2005, about 200 tonnes of MOX was produced, incorporating 12-14 tonnes of plutonium. MOX production capacity is presently around 225t/yr, using 15-18 tonnes of plutonium. Since 1963 over 400 tonnes of plutonium has been used in MOX.

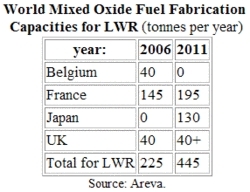

World Mixed Oxide Fuel Fabrication Capacities for LWR (t/yr)

| 2006 |

2008 |

2012 | |

| France | 145 | 195 | 195 |

| Japan | 0 | 0 | 130 |

| UK | 40 | 40 | 40 |

| Total for LWR |

185 | 235 | 445 |

In 2006 a 40 t/yr Belgian plant closed and in April 2007 the French Melox plant was licensed for an increase in production from 145 to 195 t/yr. Also the Sellafield MOX plant in UK was downrated from 128 to 40 t/yr. Japan is planning to start up a 130 t/yr MOX plant at Rokkasho in 2012..

MOX is also used in fast neutron reactors in several countries, particularly France and Russia. It was first developed for this purpose, with experimental work being done in USA, Russia, UK, France, Germany, Belgium and Japan. Today, Russia leads the way in fast reactor development and has long-term plans to build a new generation of fast reactors fuelled by MOX. The world's largest fast reactor, the 800 MWe BN-800, is currently under construction at Beloyarsk, in the Ural Mountains of Russia, and due to start up in 2010.

At present, the output of reprocessing plants exceeds the rate of plutonium usage in MOX, resulting in inventories of (civil) plutonium in several countries. These stocks are expected to exceed 250 tonnes before they start to decline after 2010 as MOX use increases, with MOX then expected to supply about 5% of world nuclear reactor fuel requirements.

MOX reprocessing and further use

Used MOX reprocessing has been demonstrated since 1992 at the La Hague nuclear facility in France. In 2004, the first reprocessing of used MOX fuel was undertaken on a larger scale with a continuous process. Ten tonnes of MOX irradiated to about 35,000 MWd/t and a plutonium content of about 4% was involved. In this process, the main problem of fully dissolving PuO2 was overcome.

However, at present the general policy is not to reprocess used MOX fuel, but to store it and await the advent of fuel cycle developments related to Generation IV fast neutron reactor designs.

MOX & disposition of weapons plutonium

For disposal of weapons-grade plutonium, special arrangements are envisaged. A multinational consortium is to finance the construction of a MOX plant in Russia (Tomsk, Siberia), particularly to utilize Russian weapons-grade plutonium (at 2 t/yr), and a similar plant is being built in USA (at the Savannah River Site, South Carolina). These facilities will enable ex-military plutonium from disarmament to be permanently destroyed as it is "burned" in reactors as MOX. Meanwhile, the first fuel assemblies with MOX from US weapons plutonium and fabricated at the Melox plant in France are being burned on a trial basis in USA.

The objective of this MOX fuel program is to destroy one-third of weapons-grade plutonium and convert the remainder to reactor-grade plutonium (with significant levels of plutonium-238 & plutonium-240), radically degrading its isotopic quality and potential for weapons.

Plutonium-thorium fuel

Since the early 1990s, Russia has operated a program to develop a thorium-uranium fuel, with more recent emphasis on the utilization of weapons-grade plutonium in a thorium-plutonium fuel. The program is based at Moscow's Kurchatov Institute and involves the US company Thorium Power and US government funding to design fuel for Russian VVER-1000 reactors.

The program is described in the Thorium paper.

With an estimated 150 tonnes of weapons plutonium in Russia, the thorium-plutonium project would not necessarily cut across existing plans to make MOX fuel.

Further Reading

- WNA paper on Mixed oxide fuel (MOX)

- European Nuclear Society. The European Pressurized Reactor (EPR).

- International Nuclear Safety Center. Third-Generation VVERs.

- International Nuclear Safety Center. Overview of Fast Reactors in Russia and the Former Soviet Union (Mixed oxide fuel (MOX)) .

- U.S. Energy Information Administration. New Reactor Designs.

- Westinghouse Electric Company. The AP1000 Nuclear Reactor.

- IAEA 2003, Status and Advances in MOX Fuel Technology, Technical Review Series # 415.

- OECD/NEA 2007, Management of Recyclable Fissile and Fertile Materials, NEA # 6107.