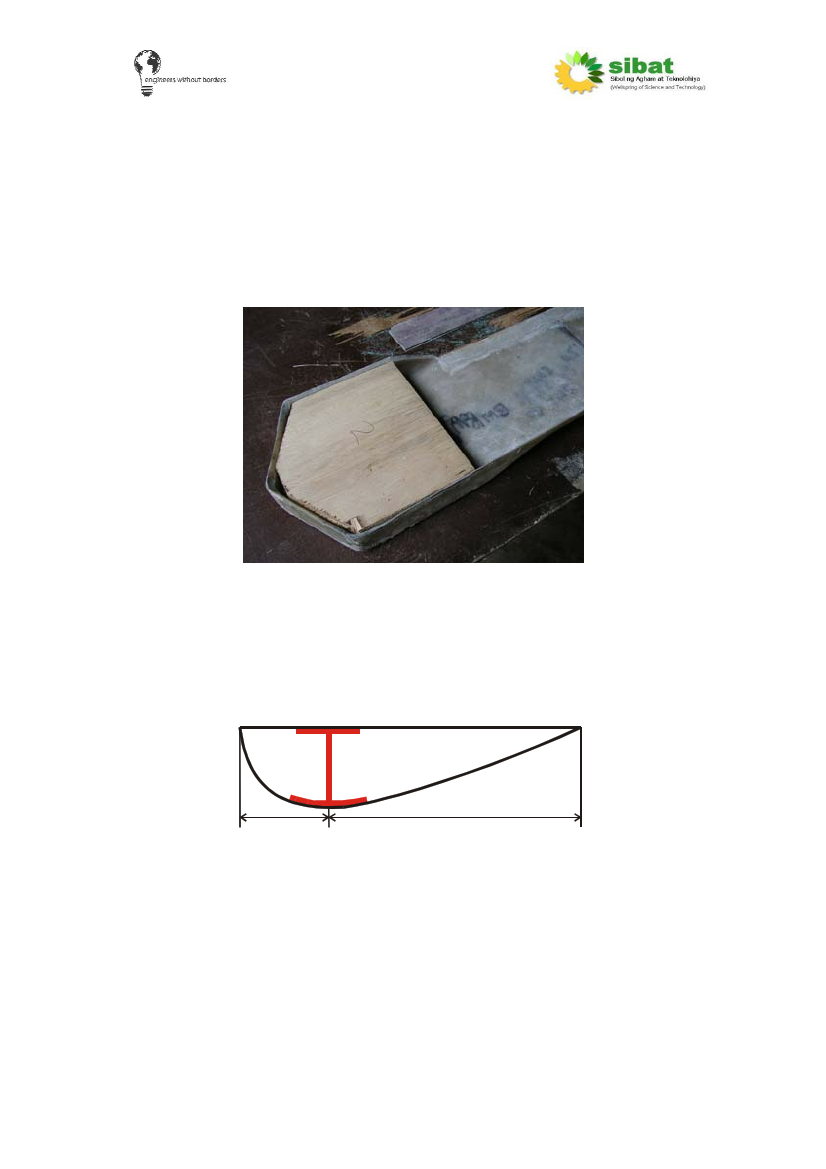

Blade root

A wooden core is required at the blade root - where the blade is screwed to

the blade hub. The blade root should fit snugly in the root of the blade and go

far enough down the blade so that all the screws will bite into the wood core.

In this case the wooden piece was 7.5” width and 8” length at the longest part.

This was made from a number of layers of plywood (marine grade if possible).

In this case four layers of ½” plywood were used. This fitted well, although

required some sanding down where the resin was not perfectly flat. The layers

of plywood were glued together and clamped to form a single block. Once the

part is dry the edges can be filleted to fit the inner surface of the blade.

‘Stringer’ manufacture

As shown in the blade design, a fibreglass ‘stringer’ is used through the wind

turbine blade. This greatly adds rigidity to the blade which is important to

prevent the blade snapping under the high bending force. The stringer is also

used to hold the windward and backward blade halves together.

Cross-section of the blade to show the ‘Stringer’:

Approx 1/3

Approx 2/3

1: Make a thin (3-4mm thick), flat sheet of fibre glass. This must be at least as

long as the blade (1.8m) and 20cm wide. This is made from at least three

layers of 200gsm WC. This can be made by laying the fibre glass sheet on a

flat, waxed surface. It can then be covered with the general purpose ‘inner

layer’ resin mix. This will need approximately 200g of inner layer resin. Leave

to dry (overnight).

25