DRYIT Semi-Continuous Tray Drier

Practical Action

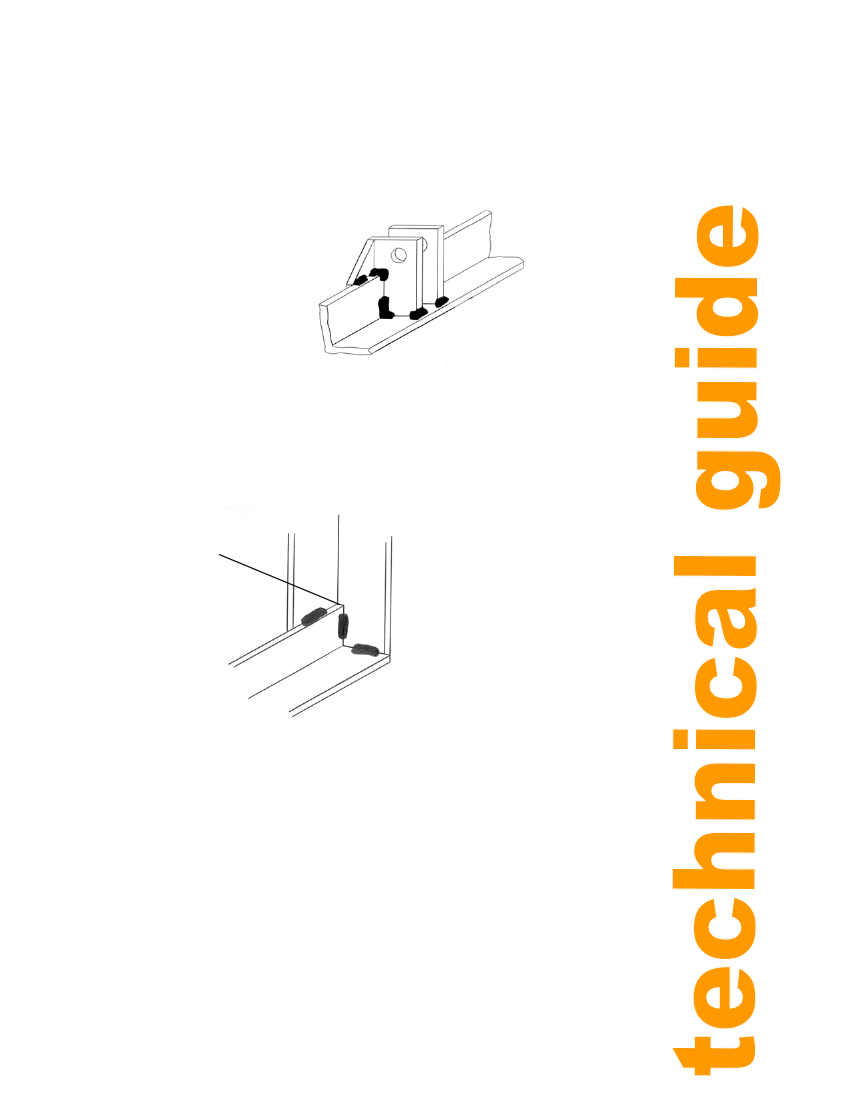

3) Cut out and drill the finger supports (see TD002) and then weld them to the two bottom

beams, as shown in figure 11. Minimise distortion by restraining the lower beam (with vice,

clamp etc) during welding and cooling and by keeping the weld material uiaed to a minimum.

Note that weld is not applied to the underside of the over hang. This area must be clear, for

positioning of the base joining pads.

No weld here

Figure 11: Finger supports

CORRECT POSITIONING OF THE SUPPORTS IS ESSENTIAL FOR CORRECT

FUNCTIONING OF THE LIFTING FINGERS. THE POSITIONING AND DIMNENSIONS OF

ALL MEMEMBERS ARE GIVEN IN TD 002.

4) Chamfer the ends of the lower beams to achieve a square, flush fit with the legs, as

shown in figure 12.

3mm chamfer

5) Weld two legs to each bottom

beam, ensuring they are square

Figure 12: Chamfered end to lower beam

Now assemble these with the

rectangle and add the centre beam,

centre supports, centre legs and

bearing block supports. Do not

weld on the top side of the bearing

supports as the bearing must sit

flat. Note: the cut-outs in the centre

beam are for the bearing shafts.

Take care to ensure the frame is

square and vertical before full

welding.

DO NOT drill any holes apart from those in the finger supports at this stage. The hole

positions shown in the drawing TD002 are theoretical and are actually located by marking

through holes in other assemblies, as described in General Assembly

13