Piping Systems

The piping system connects the biogas plant with the gas appliances. It has to be safe,

economic and should allow the required gas-flow for the specific gas appliance. Galvanized

steel (G.I.) pipes or PVC-pipes are most commonly used for this purpose. Most prominently,

the piping system has to be reliably gas-tight during the life-span of the biogas unit. In the

past, faulty piping systems were the most frequent reason for gas losses in biogas units.

PVC piping

PVC pipes and fittings have a relatively low price and can be easily installed. They are

available in different qualities with adhesive joints or screw couplings (pressure water pipes).

PVC pipes are susceptible to UV radiation and can easily be damaged by playing children.

Wherever possible, PVC pipes should be placed underground.

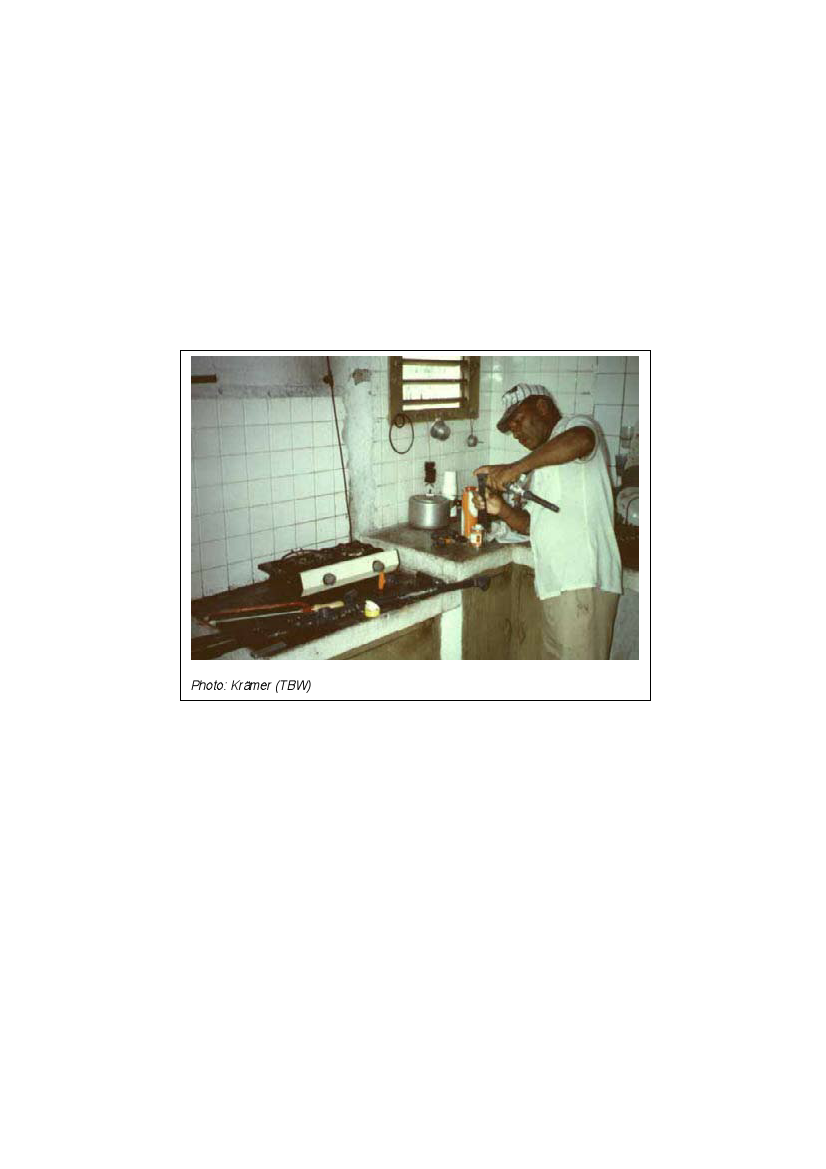

Figure 26: Final touches on a piping system with PVC pipes

Photo: Krämer (TBW)

Galvanized steel piping

Galvanized steel pipes are reliable and durable alternatives to PVC pipes. They can be

disconnected and reused if necessary. They resist shocks and other mechanical impacts.

However, galvanized steel pipes are costly and the installation is labor intensive, therefore

they are only suitable for places where PVC is unavailable or should not be used.

Pipe diameters

The necessary pipe diameter depends on the required flow-rate of biogas through the pipe

and the distance between biogas digester and gas appliances. Long distances and high flow-

rates lead to a decrease of the gas pressure. The longer the distance and the higher the flow

rate, the higher the pressure drops due to friction. Bends and fittings increase the pressure

losses. G.1. pipes show higher pressure losses than PVC pipes. The table below gives some

values for appropriate pipe diameters. Using these pipe diameters for the specified length

and flow rate, the pressure losses will not exceed 5 mbar.

48