Water-jacket floating-drum plants

Water-jacket plants are universally

applicable and easy to maintain. The

drum cannot get stuck in a scum layer,

even if the substrate has a high solids

content. Water-jacket plants are

characterized by a long useful life and a

more aesthetic appearance (no dirty

gas-holder). Due to their superior

sealing of the substrate (hygiene!), they

are recommended for use in the

fermentation of night soil. The extra cost

of the masonry water jacket is relatively

modest.

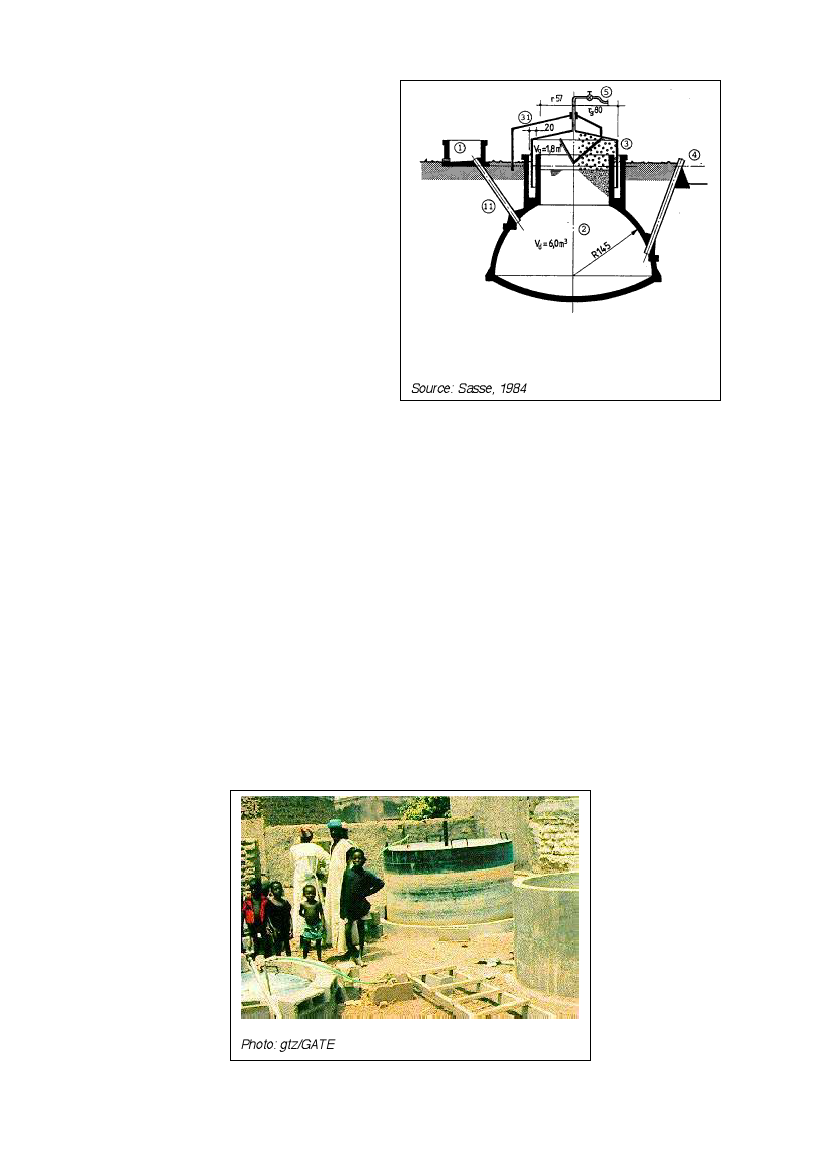

Figure 8: Water-jacket plant with external guide

Material of digester and drum

frame. 1 Mixing pit, 11 Fill pipe, 2 Digester, 3

Gasholder, 31 Guide frame, 4 Slurry store, 5 Gas

The digester is usually made of brick,

concrete or quarry-stone masonry with

pipe

Source: Sasse, 1984

plaster. The gas drum normally consists

of 2.5 mm steel sheets for the sides and

2 mm sheets for the top.

It has welded-in braces which break up surface scum when the drum rotates. The drum must

be protected against corrosion. Suitable coating products are oil paints, synthetic paints and

bitumen paints. Correct priming is important. There must be at least two preliminary coats

and one topcoat. Coatings of used oil are cheap. They must be renewed monthly. Plastic

sheeting stuck to bitumen sealant has not given good results. In coastal regions, repainting is

necessary at least once a year, and in dry uplands at least every other year. Gas production

will be higher if the drum is painted black or red rather than blue or white, because the

digester temperature is increased by solar radiation. Gas drums made of 2 cm wire-mesh-

reinforced concrete or fiber-cement must receive a gas-tight internal coating. The gas drum

should have a slightly sloping roof, otherwise rainwater will be trapped on it, leading to rust

damage. An excessively steep-pitched roof is unnecessarily expensive and the gas in the tip

cannot be used because when the drum is resting on the bottom, the gas is no longer under

pressure.

Floating-drums made of glass-fiber reinforced plastic and high-density polyethylene have

been used successfully, but the construction costs are higher compared to using steel.

Floating-drums made of wire-mesh-reinforced concrete are liable to hairline cracking and are

intrinsically porous. They require a gas-tight, elastic internal coating. PVC drums are

unsuitable because they are not resistant to UV.

Figure 9: Floating-drum plant in Burkina Faso

Photo: gtz/GATE

12