bracket and glass for protection.

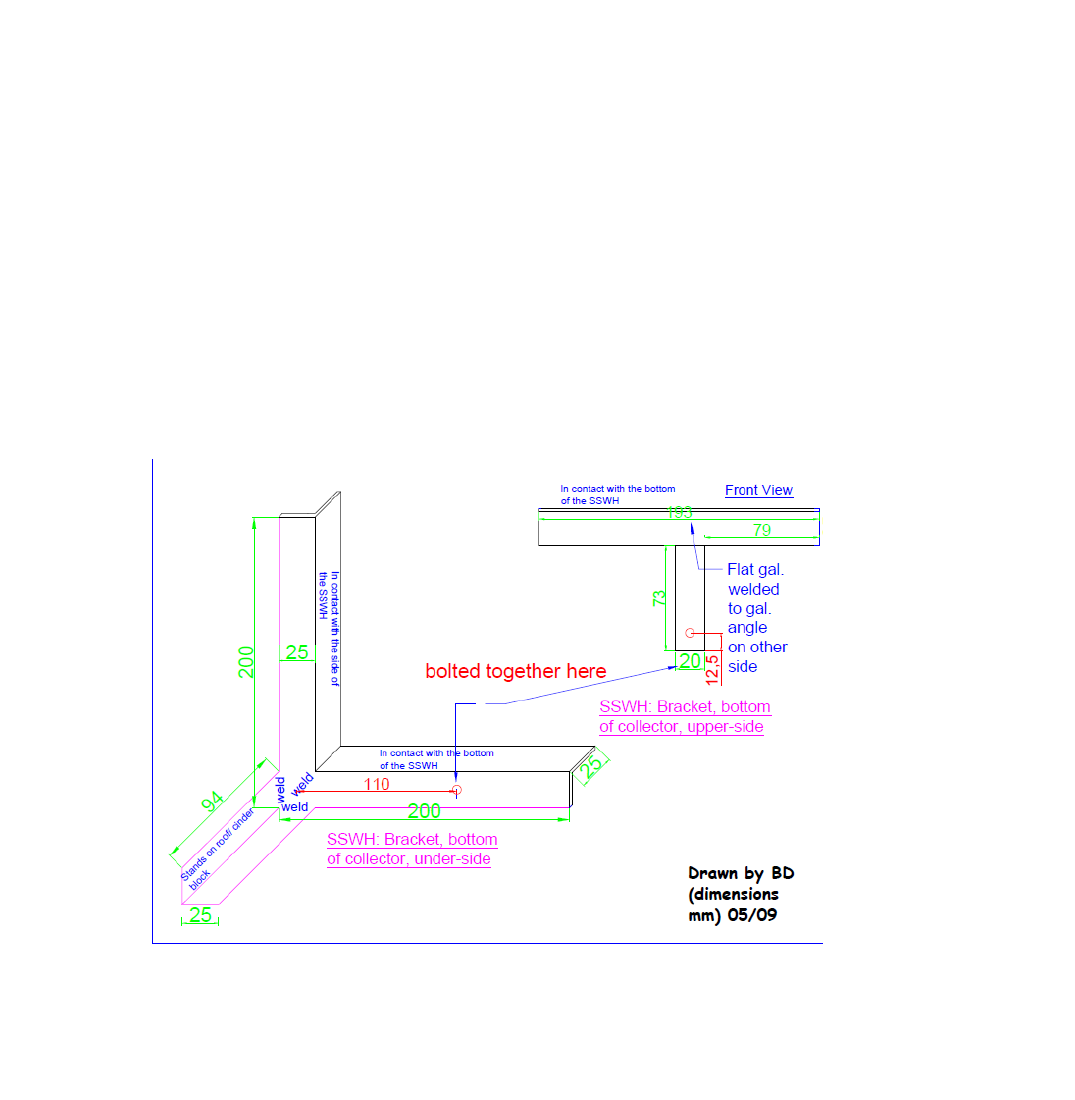

2.3.4 Bottom of collector underside bracket:

Cut two 200mm lengths of 20 x 25mm x 2mm angle iron. This can be done with a hacksaw; if

using a chop-saw allow for the thickness of the disc. Cut the first with the saw at 45°, making

an angled cut on one side and a straight cut with an angled saw on the other. Cut the second

200mm length at – 45°.

These two lengths now join together to form a right-angle. Weld together into a right-angle

formation. The 45° weld identifies the horizontal side. Position so that the vertical edge faces

downwards. Drill a 6.5mm hole, 110mm from the weld on the right hand (200mm) section

(vertical side.)The exact position will be determined by alignment with the connecting hole in

the underside bracket, when they are both in position with the collector in between.

Cut a 94mm length of 25 x 25 x 2mm angle iron. Position vertically, with its angled edge

continuing the line formed by the 90° welded join (of the right-angle you have just made). The

2mm cross section is to be welded to the 2mm sides of this right-angle.

17