2.2 The Frame

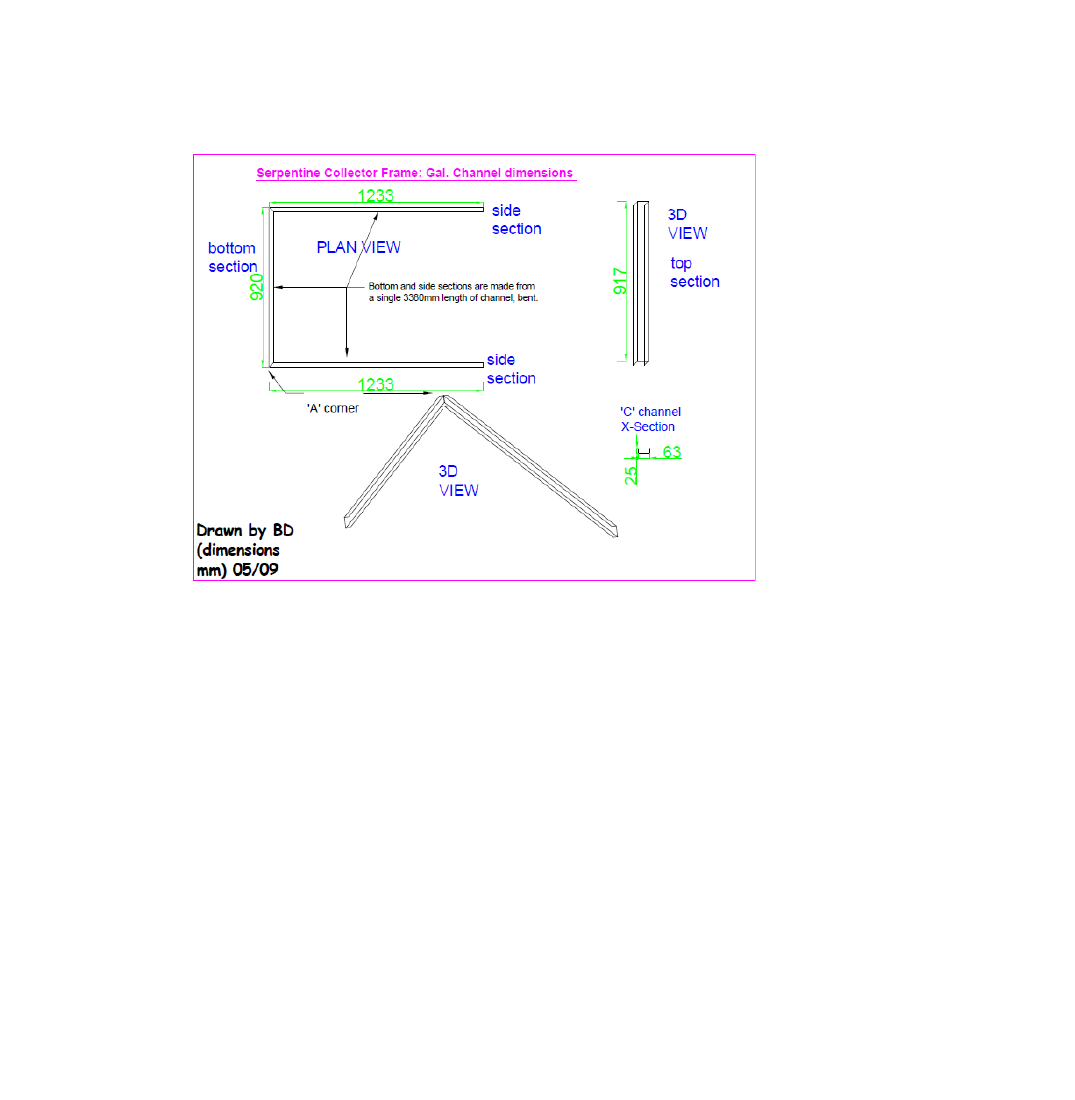

The absorber size determines the dimensions of the frame.

2.2.1 Side Sections

Use tip snips to cut the channel into a 917mm section and a 3400mm section. The 3400mm

section will form the sides and bottom of the frame; it will be bent at approximately 1233mm

and 2153mm, forming 1233mm 920mm 1233mm sections.

Drilling the inlet pipe hole in the 920mm section is instrumental for ensuring that the frame is

square. Therefore the procedure for making the side sections is as follows:

1. Provisionally mark the points for cutting and bending: 1238mm and 2158mm. This

allows an error margin for the 1233mm 920mm 1233mm sections.

2. On the 920mm section mark the position of the inlet hole for the pipe. If the pipe inlet

is not at right-angles to the frame, this inlet hole will need to be too wide, causing

heat loss. If necessary bend the pipe (with care) so that the inlet is vertical.

3. Drill the inlet using a 22mm hole saw bit. File the hole so that it will fit over the pipe

easily without causing significant heat loss.

4. With the inside of the channel flush with the absorber plate remark the 920mm

bottom section. The cutting / bending points marked by this section should leave at

11