-

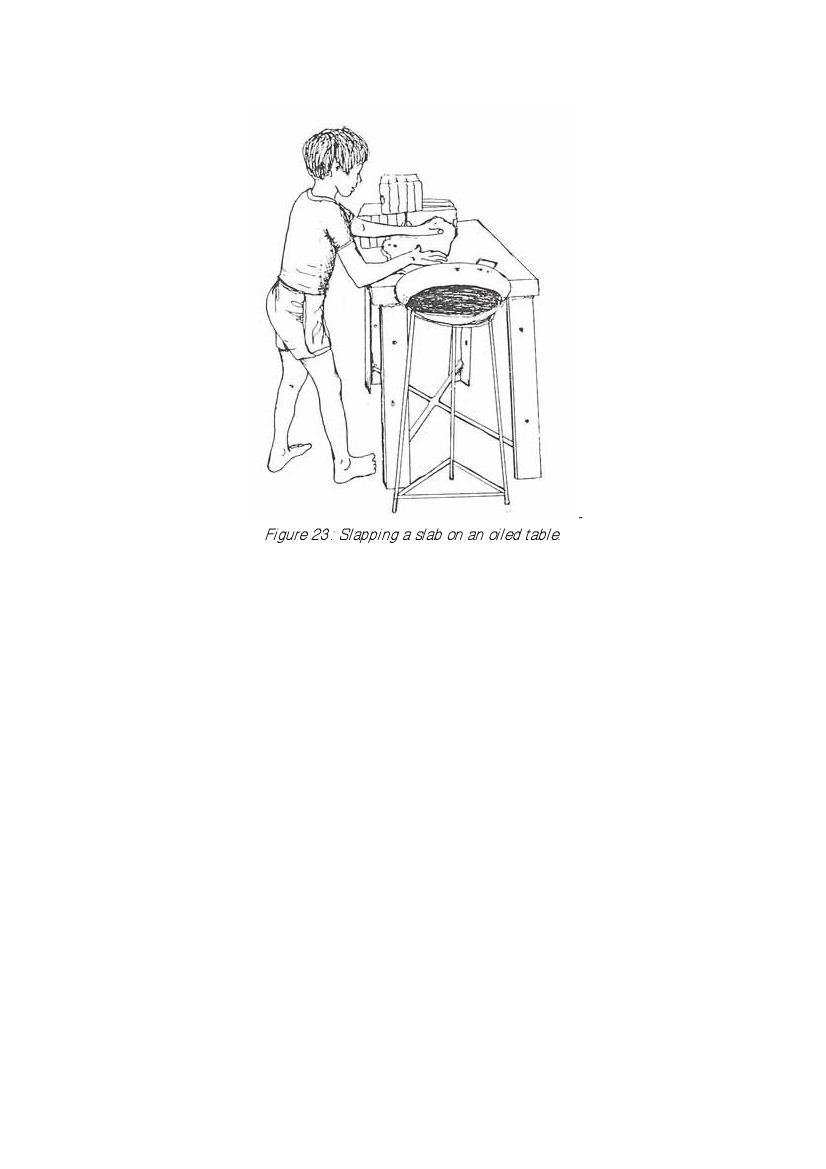

Figure 23: Slapping a slab on an oiled table.

The oiled slab is then transferred to the bottom die, which is slid under the upper die

(attached to the flywheel, figure 23). The fly wheel is then spun down onto the clay.

Depending on the weight of the flywheel, the strength of the spinners, and the size of the tile,

it may require two impacts of the dies to press the tile adequately. The bottom die is then slid

out and tilted to release the tile onto the pallet (figure 25). It should be noted that up to 15

per cent of the pressed tiles are rejected at this stage due to pressing defects. These are

collected and put back through the clay preparation cycle for re-use. Figures 24 and 25 give

an overview of typical production teams on both the single and double action presses.