Construction of water projects

|

Construction of water projects

Importance:

high

|

|

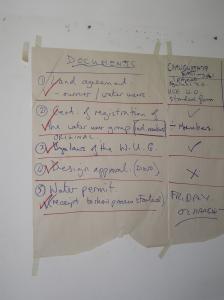

It is important to obtain the required permits, as described in the data sheet on Surveys, designs and permits for water projects, before starting any construction of water supply systems. Structures built without these legal requirements are illegal and might have to be destroyed without any compensation.

In Kenya, the Water Services Boards (WSBs) are forming their policy on construction of small water projects for individuals and community groups. Abstraction of shallow and deep ground water by means of hand-dug wells and boreholes, as well as abstracting water from streams, must be approved by the WSBs and an annual fee paid for the extraction permit.

The Water Resource Management Authority published a document on 25/02/09 entitled "Guidelines for Determination of Permit Classification for Water Storage Structures" which :says:

"First, small pans, where the water is held below ground level, do not require a permit provided the capacity is less than 10,000 m3. If the capacity will be greater than this the community, or the farmer should apply to the Regional office of the Water Resource Management Authority (WRMA) for permission to construct."

Also permits from WSB and the National Environmental Management Authority (NEMA) must be obtained before wells, intakes, boreholes, subsurface dams, weirs and sand dams are built in seasonal riverbeds as well as other types of water supply systems. Collection of rainwater from roofs of private buildings does not require any approvals.

|

|

Seasonal Work Plan

The construction work of such structures should take place in the beginning of the short dry season or in the middle of the long dry season when there is no risk of an unexpected thunder shower that can flood the construction site.

Excavation of trenches for pipes, and the laying of pipes, should also take place in the dry season when the fields have been harvested to avoid spoiling crops in the field. Other activities that demand much manual labour should also be implemented when the farmers are less busy in the dry seasons.

Excavation of trenches for pipes, and the laying of pipes, should also take place in the dry season when the fields have been harvested to avoid spoiling crops in the field. Other activities that demand much manual labour should also be implemented when the farmers are less busy in the dry seasons.

Another big advantage of constructing water projects during dry seasons is that the provision of water is usually the biggest issue during those periods. It is therefore fairly easy to mobilize and organize people to carry out manual work.

Financial capacity

Preferably, all the money required for the construction work should be available if the structure is expected to be completed within a short period. Alternatively, the structure can be built in stages according to the availability of funds.

A good example is where small earth dams are built in stages and financed by giving two jerry-cans of water to each person who has excavated 2 cubic metre of soil or where water is sold for cash which is used to pay for labourers doing the excavation works.

For further information on seeking funds for water projects click here

See also datasheet on water as a business.

When interviewing artisans and contractors for their ability to construct a certain type water project or any other type of construction works, it is very rare to hear any doubts from the builders. Most builders are very convinced that they are the best ones who can be hired for that job, although they have no proof of having passed a trade test or having any Letters of Recommendation from former clients. Rather unfortunately, their last successful construction works were built so far away that a client would not like to spend a couple of days travelling there to see for himself. Some builders may be smart enough to give a mobile number of a very satisfied client who may, in fact, be the builder's friend doing him a favour in exchange for a few beers in the evening.

One of the best methods to sort out doubtful builders is to ask them technical questions, e.g.:

1. What is the correct mixture and thickness of cement to sand and ballast for concreting the foundation and floor of water tanks?

- The answer is 15 cm of 1:3:4 followed by a 2 cm coat of 1:3 mortar onto which NIL (cement slurry) is applied the same day for water proofing.

2. Which type sand should be used for concrete?

- The answer is coarse textured river sand

3. Which type of sand can be used for final plastering?

- The answer is fine textured river sand, not sand collected from dirt roads.

4. What happens if cement is mixed with sand and water that is not applied within one hour?

- The answer is that the strength of cement will be reduced to half.

5. For how long should concrete and plaster work be cured, that is to be keep moist under shade?

- The answer is 28 days. If cured less, the cement loses its strength.

6. What does this technical design drawing show?

Where many structures are going to be built, e.g. for a community water programme, it is a good investment to train some 20 engineers and 40 builders while they construct the first structures.

For more information on training of project stuff click here.

It is wise to employ an artisan or a contractor before procuring and delivering building materials to a construction site to prevent e.g. wasting money on the wrong type of sand or off-loading building materials where it becomes inconvenient for the construction process. There are several differences between employing artisans and contracting contractors, such as:

Artisans are paid a daily salary for an unknown number of days as agreed verbally between the client and the artisan before the work starts. This is the most popular method of undertaking construction works in rural areas because both the client and the artisan can cancel the agreement any time provided the client pays the artisan for the number of days that he has worked.

This type of flexible agreement is excellent where clients can supervise the artisans but is often abused by artisans if they are not supervised on a daily basis.

|

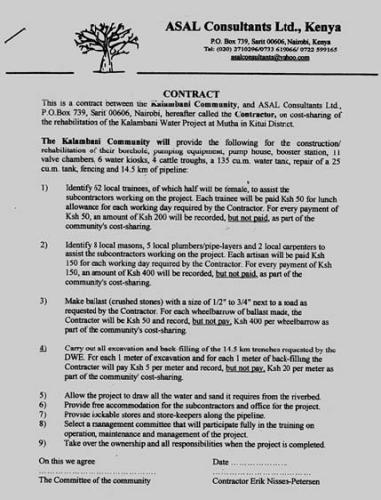

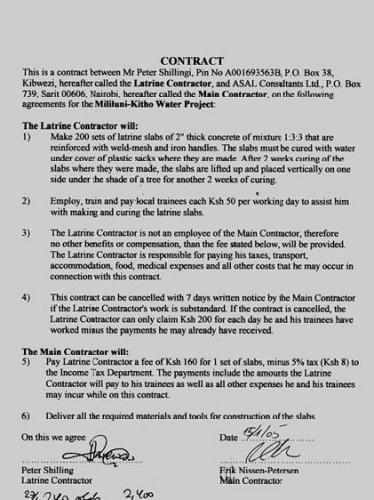

Contractors quote a fixed price for a certain construction work that is described in details either in a survey and design report or verbally by the client. In both cases, the contractor and the client will haggle about the quoted price while discussing whether food, accommodation, transport and unskilled labourers are included.

While this kind of verbal contract is accepted for small private construction works, it should be formulated and signed in a contract for larger private and community building projects. Such contracts should have clauses on the rates of payments, retention fee, health and accident insurance, tax payments and other financial issues as shown below. Although such non-flexible contracts usually increase the cost of the construction works, they require less supervision by the clients and reduce the overall cost of the project. However, in case of disagreements between the client and the contractor that may lead to cancellation of the contract, they have to make a financial settlement which may require one or two impartial persons to arbitrate. In negotiations with artisans and contractors it is useful to know the average number of working days it will take to built various types of structures. The following data is based on more than three decades of actual construction works of the types of water projects listed below. As a rule of thumb, a contractor earns a fee being double of an artisan`s salary and an artisan earns a salary being double of an unskilled labourer`s salary. |

Average working days on various types of water projects

| Water source |

Structure

|

Artisans or contractors | Unskilled labourers |

| Roof catchments | 3 cu.m. ferro-cement jar | 5 | 5 |

| Roof catchments | 5 cu.m. concrete in situ tank | 8 | 16 |

| Roof catchments | 10 cu.m. brick or block tank | 10 | 20 |

| Roof catchments | 11 cu.m. ferro-cement tank | 10 | 20 |

| Roof catchments | 23 cu.m. ferro-cement tank | 20 | 30 |

| Roof catchments | 46 cu.m. ferro-cement tank | 28 | 42 |

| Roof catchments | 90 cu.m. ferro-cement tank | 42 | 80 |

| Shallow groundwater | 8 metres deep hand-dug well | 24 | 144 |

| Dry sandy riverbeds | 18 metres long subsurface dam | 22 | 280 |

| Dry sandy riverbeds | 50 metres long weir | 26 | 336 |

| Dry sandy riverbeds | 28 metres long sand dam | 42 | 560 |

| Roads and farmland | 130 cu.m. berkad ground tank | 40 | 120 |

| Roads and farmland | 500 cu.m. charco earth dam | 30 | 500 |

| Roads and farmland | 500 cu.m. hillside earth dam | 20 | 250 |

| Roads and farmland | 500 cu.m. valley earth dam | 20 | 250 |

| Rock outcrops | 300 cu.m. rubble masonry dam | 75 | 200 |

| Rock outcrops | 50 cu.m. rubble block water tank | 30 | 100 |

| Rock outcrops | 500 cu.m. hillside earth dam | 20 | 250 |

|

| A contract with another contractor

on making 200 latrine slabs |

| © E. Nissen-Petersen, Kenya |

Quotations and procurements of building materials

According to normal procedures at least three quotations of each item of building materials should be obtained from various hardware shops and other suppliers.

In practice this is done by photocopying the BQ with its quoted prices, by a quality surveyor, covered by a blank paper in a dozen copies. These copies of the BQ showing no prices are presented to owners of hardware shops and suppliers while asking them if they would be interested in giving a quotation for those items on the BQ which they may have for sale. The suppliers should also quote their delivery time and their mode of payments, such as should everything be paid in advance or upon delivery or is it sufficient to pay, say a 50% down-payment.

The obtained quotations are laid side by side in order to identify the cheapest supplier for each item. Thereafter the quoted delivery times and payment modes are compared and the most favourable suppliers are identified. Often the cheapest supplier is unable to deliver their goods within the given time.

For community water projects, the communities are expected to deliver locally available materials such as sand, hardcore stones, ballast and water to the construction sites as part of their cost-sharing on the construction

.

As mentioned under the entrepreneurial approach, great cost reductions can be achieved on the implementation schedule by paying, to the communities, 50% cash of procurement cost of locally available materials, delivered to the construction sites, while the other 50% is accounted, but not paid, as their contribution. (See data sheet on "Community Management of Water Sources".

The requirements of labour and materials with estimated costs are usually listed in Bills of Quantities (BQ) of which an example is shown below.

The requirements of labour and materials with estimated costs are usually listed in Bills of Quantities (BQ) of which an example is shown below.

Bill of quantities and cost of a 90 cu.m. tank built of ferro-cement

| Description | Unit | Quantity/ Days | Unit cost (Ksh) | Total cost (Ksh) |

|

Labour cost Artisan Labourers Cost of labour |

Artisans Labourers |

3 x 14 days 4 x 20days |

400/day 200/day |

16,800 16,000 ----------- 32,800 |

| Materials

Bags of cement Lime River sand Crushed stones Burnt bricks, 4' x 6' x 10' Water Weld mesh, 2.4 x 1.2 g8 Chicken mesh 25mm, 0.9m Twisted bars, Y12 Barbed wire g12.5 G.I pipe, 1½' G.I elbow, 1½' G.I pipe, ¾' (20mm) G.I tap, elbow, socket, nipple, ¾' uPVC, 4' sewage pipe Galvanized coffee mesh Mosquito mesh Timber, 6' x 1' Timber 2' x 3' Poles Bolt 6 x 120mm Oil-drum sheets (old discharged ones) Plastic bag Angle iron 25 x25mm Plastic basin Sisal twine Nails 3' Cost of materials |

50 kg bags 25 kg bag tonnes tonnes units oil-drums sheets metres metres kg metres unit metres tap - unit metres square metres square metres metres metres units units units units units units kg kg |

73 2 17 1 500 45 25 100 5 100 4 1 9 1 5 1 0.5 60 60 12 12 48 50 16 1 3 3 |

600 400 200 600 5 100 370 110 60 150 420 80 200 700 133 200 100 75 75 40 50 Free 30 120 100 70 80 |

43,800 800 3,400 600 5,000 4,500 9,250 11,000 300 15,000 1,680 80 1,800 700 670 200 50 4,500 4,500 480 600 Free 1,500 1,920 100 210 240 ------------ 112,880 |

| Transport of materials

Hardware lorries Tractor trailer loads Cost of transport |

7 tonnes 3 tonnes |

1 loads 14 loads |

5,000 900 |

5,000 12,600 ----------- 17,600 |

| Total cost and value of 90 cu.m tank

built of ferro-cement |

163,280 |

Be aware that the items measured in tonnes, such as sand and crushed stones (ballast), are difficult to measure without a weighing station and some suppliers are therefore tempted to cheat. Such suppliers can, however, be controlled by converting the volume of sand and ballast into tonnes using the following method:

1) Measure in metres the length, width and depth of sand in a loaded lorry. Multiply these three figures to get the volume of cubic metres, e.g.

length 3.0 m x width 2.0 m x depth 0.5 m = 3 cubic metres load.

2) The handbook "Field Engineering" by F. Longland gives the following data:

Dry sand weights on average 2.2 tonnes per cu.m.. Therefore 3 cu.m. sand weights 6.6 tonnes.

Crushed granite stones weight 2.7 tonnes per cu.m. Therefore 3 cu.m. stones weights 8.1 tonnes.

While it is advisable to have an experienced builder from the community on the construction site to check whether the cement is fresh and the sand is coarse and clean from a riverbed when the suppliers bring in their materials, the hired artisan or contractor should not waste his time being on the site before all materials are stored there.

A community water project may often have hundreds of community members who should be managed to carry out useful work on constructing their water projects as part of their cost-sharing. This is achieved by the members electing practical persons among themselves to form a Project Committee responsible for the successful completion of the construction works. They learn the techniques and methods for this work during their First Community Training.

The committee will enter their members' names in a Muster Roll and group them into work gangs according to their ages and capacities as follows:

1. Elderly men will clear the access road and construction site of trees, bushes and stumps.

2. Elderly women will collect hardcore stones and crush some of them into ballast as well as cook food and nurse babies.

3. Middle aged men and women will bring river sand, hardcore stones and ballast to the construction site by means of tractor trailers, ox- and donkey carts, wheelbarrows, bicycles or sacks.

4. Young men and women will be trained as artisans while assisting the artisans and contractors constructing the water project. Those trainees who may wish, and who are capable, are sent to take trade tests where the successful ones will obtain certificates as artisans.

5. Young women having completed their education at Secondary Schools will be trained as store-keepers and office staff while doing the actual job under the supervision of experienced trainers, preferably from the community itself.

The work discipline is maintained by means of the muster rolls. Failures, due to coming late to work or being absent, are recorded and fines may be imposed according to the by-laws. The fines are kept by the Treasurer of the committee and usually spent on buying sodas and biscuits for important visitors.

Community members who have not worked on construction of a water project have to pay a considerable cash payment to the committee for being allowed to be a member and to draw water from the project.

Before completion of the construction works, the committee members attend the Second Community Training dealing, among other issues, with financial management.

For further information on community training click here.

Rural builders know how to build small houses of burnt bricks and roofed with corrugated iron sheets but often lack proper training and experience to work with cement, mortar and concrete.

For example, in the mornings they may mix all the mortar or concrete they need for several hours without knowing that cement loses up to 50% of its strength one hour after it has been mixed, if it has not been applied.

Also rural builders often do not know that if mortar and concrete works are not cured by keeping them moist under cover for 28 days, the cement will lose even more strength. This neglect of proper handling of cement works does not matter for small rural houses but when this lack of skills is applied to water reservoirs, the results can be observed in the country-wide graveyards of failed water tanks and other structures.

Whenever a water programme is being planned for rehabilitation of old water projects or construction of new water projects, it should include a training course for community members identified by the development committee. The training can be implemented for a reasonable cost by using the hands-on methodology of learning-by-doing by which the trainees assist trained builders in the construction works.

A training course should deal with the types of water structures having the most potential for the people living in a certain environment. In the driest parts of the world the most potentially useful types of rainwater harvesting projects depend on the catchment areas and not the rainfall because where there is less rain it can be compensated for by larger catchments.

The table below prioritizes various types of catchment areas with the most viable structures for harvesting rainwater for domestic and agricultural use.

The table below prioritizes various types of catchment areas with the most viable structures for harvesting rainwater for domestic and agricultural use.

| Catchment areas | Viable structures | Domestic or agricultural | |

| 1 | Seasonal sandy water courses, dry riverbeds, luggah, wadi and ephemeral streambeds | Wells, shallow boreholes, subsurface dams, weirs and sand dams | Both |

| 2 | Roads, tarmac, murram and dirt surfaces | Ponds, earth dams, ground tanks, macro irrigation | Agricultural |

| 3 | Rock surfaces above and below ground level | Masonry walls, water tanks and hillside earth dams | Both |

| 4 | Roofs, except thatched | Water tanks | Domestic |

| 5 | Valleys | Valley earth dams with wells | Both |

| 6 | Flat land | Charco earth dams with wells | Both |

| 7 | Rolling land | Hillside earth dams with wells | Both |

| 8 | Hills | Gravity flow from springs | Domestic |

Training courses

This section is based on the experience gained from implementing half a dozen training courses on water supply in arid and semi-aid zones of Africa and Asia.

After some meetings, the consultant presented a project proposal to a client who wanted to assist hundreds of communities with construction of small water projects. The methodology had to be implemented through the Water Services Boards by self-employed engineers trained as consultants and local builders trained as contractors. The engineers and builders had to be identified from the communities concerned.

After some meetings, the consultant presented a project proposal to a client who wanted to assist hundreds of communities with construction of small water projects. The methodology had to be implemented through the Water Services Boards by self-employed engineers trained as consultants and local builders trained as contractors. The engineers and builders had to be identified from the communities concerned.

A contract was signed when a detailed training programme and its budget was agreed upon. The training course was announced at relevant government offices and at places visited frequently. While applicants for the training course were preparing their documentation for the interviews, the training venues were identified, and designed with bills of quantities by some of the trainers, who also obtained the required approvals from the relevant authorities.

Other trainers obtained Implementation Agreements with the communities living near the selected riverbeds. Implementation Agreements describe the conditions and services to be delivered by the Manager of the implementing agency and the community concerned, such as:

1) Survey and design report.Other trainers obtained Implementation Agreements with the communities living near the selected riverbeds. Implementation Agreements describe the conditions and services to be delivered by the Manager of the implementing agency and the community concerned, such as:

2) Legal requirements.

3) Selection of construction site

4) Training of the community.

5) Land Agreement.

6) Registration.

7) Delivery of local labour and materials in return for the ownership of the structures built during the training course.

8) Training of men and women during the construction period in the construction, operation, maintenance and repair of their water projects.

|

While the activities listed above were implemented by some of the trainers, other trainers assisted the Manager with interviewing the, often, hundreds of applicants who arrived on the days allocated for interviews. Since some applicants have clever and lengthy ways of explaining lack of, or even false, documentation, the applicants should line up and present their documentation to a team of trainers, who sort out the disqualified applicants.

Photocopies of the applications' documentation were filed while they responded to technical and personal questions. Every applicant was informed that after short-listing; the selected persons would be informed before a certain date. If they do not receive any information, they were not selected for the training.

Engineers and technicians having diplomas and certificates were called "engineer participants", while the term "builder" covered skilled and unskilled artisans of all trades.

For every identified construction site a Survey and Design Report with a Bill of Quantities and estimated construction costs was produced. The engineer participants obtained the required approval and permits from the relevant ministries using these reports.

The engineer participants also supervised the builders being trained and communities building the structures and provided Supervision Reports to the Manager.

|

A training course on Water from Dry Riverbeds takes usually takes 12 weeks to implement as follows:

| Weeks | Activities | Actors |

| 1 | Training programme, budget, funds and advertise for participants | Manager |

| 2 | Contract 12 Assistant Trainers. Survey and Design reports | Manager and the Assistant Trainers |

| 3 | Survey and Design reports | Manager and the Assistant Trainers |

| 4 | Survey and Design reports. Implementation of agreements with communities | |

| 5 | Implementation of agreements with communities Obtain required approvals and permits | Manager and the Assistant Trainers |

| 6 | Engineer participants start Survey and Design reports | Manager and the Assistant Trainers |

| 7 | Builder participants and communities start construction works | Manager, the Assistant Trainers and Engineer participants |

| 8 | Survey and construction works continues | Manager, the Assistant Trainers and Engineer participants |

| 9 | Survey and construction works continues | Manager, the Assistant Trainers and Engineer participants |

| 10 | Survey and construction works continues | Manager, the Assistant Trainers and Engineer participants |

| 11 | Survey and construction works are completed.

Participants receive certificates and the training course is completed |

Manager and the Assistant Trainers |

| 12 | Accounts and Final Report | Manager |

- Lindquist, A. K. (Ed) (2005). Water from ponds, pans and dams. A manual on planning, design, construction and maintenance. RELMA Technical handbook No.32. Nairobi, Kenya.I SBN 9966-896-67-8

- Longland, F. (1936). Field Engineering: A Handbook on simple construction.Tanganyika Government Printer Dar es Salaam, Tanzania. (Reprinted by ITDG in 1990, under the title "Field Engineering")

- Nissen-Petersen, E. (2000). Water from Sand Rivers. A manual on site survey, design, construction and maintenance of seven types of water structures in riverbeds. RELMA Technical Handbook No.23. Sida Regional Land Management Unit, Nairobi, Kenya. ISBN 9966-896-53-8

- Nissen-Petersen, E., Madsen, B. and Katui-Katua, M. (2006). Water Water for Rural Communities. How Kenyan rural communities can create their own water supplies with assistance from the Water Services Trust Fund. Danish International Development Agency (DANIDA)